Method of testing the partial discharge of transformer

The partial discharge of transformer (reactor) can be detected by pulse current method and ultrasonic method.

1.The pulse current method.

Distributed capacitance exists between winding and core of transformer (reactor). Discharge signal is a high-frequency signal from several hundred kilohertz to several megahertz. It can be transmitted from winding to core through this capacitance, so the high frequency current can be generated in the core and core clamping parts. If the high frequency current transformer (HFCT) is installed on the grounding wire of the core or core clamping parts, the partial discharge pulse signal can be detected.

2.The ultrasonic method.

Once partial discharge occurs in the transformer (reactor), ultrasonic signals will be generated and propagated to the surrounding in a spherical form. As long as ultrasonic sensors are placed on the outer side wall of the transformer (reactor) oil tank, ultrasonic signals generated by discharge can be detected.

The two detection methods can be used together or be used alone. If these two methods are used together, it will be convenient and flexible to detect all kinds of discharge signals in transformer (reactor), and the fault location of partial discharge can be judged by the time difference between the two signals.

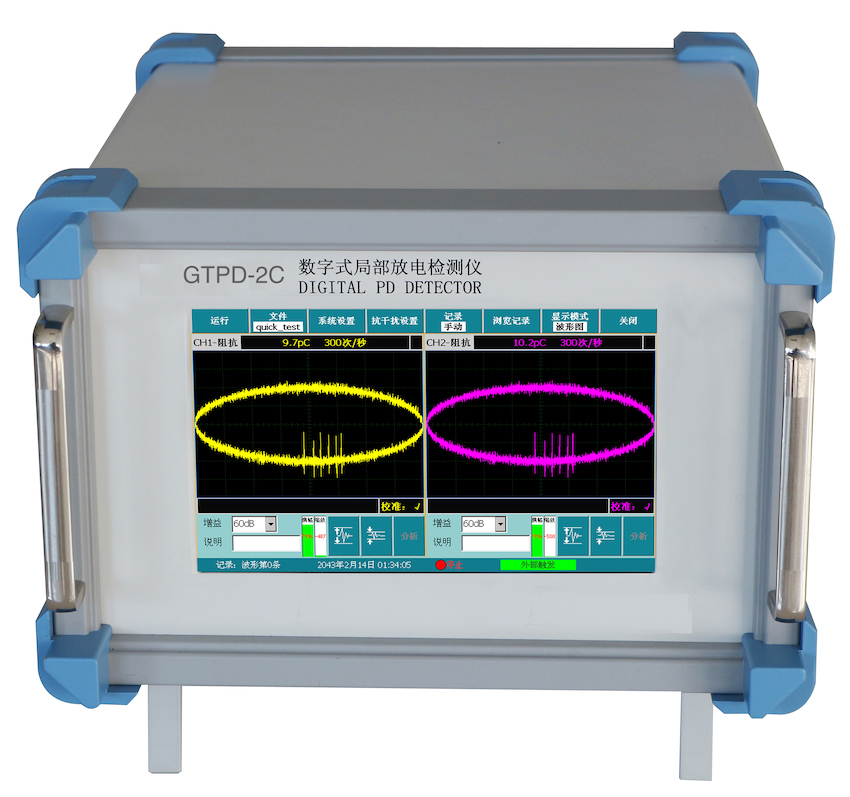

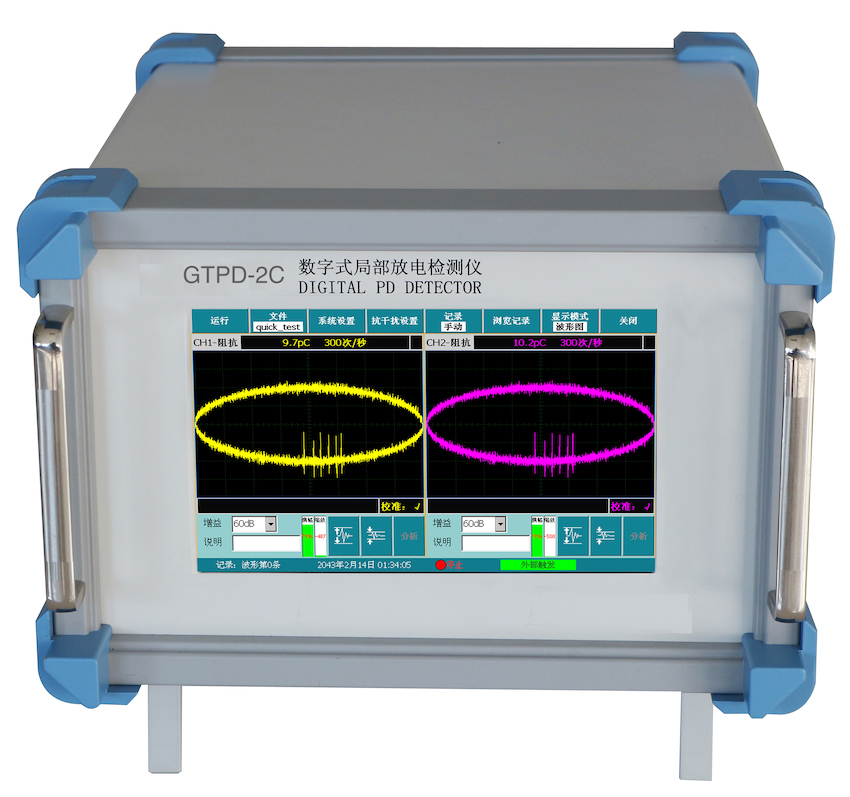

Kingrun's partial discharge tester,partial discharge measurement device GTPD-2C, adopts the two methods to detect the partial discharge of the transformers(reactors). It is welcomed by the users because of its outstanding performance.

Read More About : transformer neutral grounding resistor