Tester performance is crucial when assessing the reliability and efficiency of power transformers and distribution transformers, each subjected to specific tests tailored to their roles in the electrical grid. Power transformers, dealing with high voltages and capacities, undergo rigorous assessments like lightning impulse tests and short-circuit withstand tests to ensure durability under extreme conditions. Conversely, distribution transformers, used for medium to low voltage applications, are tested for temperature rise, sound levels, and enclosure protection to verify their operational efficiency and safety. Both types share fundamental tests such as insulation resistance and DC resistance evaluations to verify their basic electrical properties.

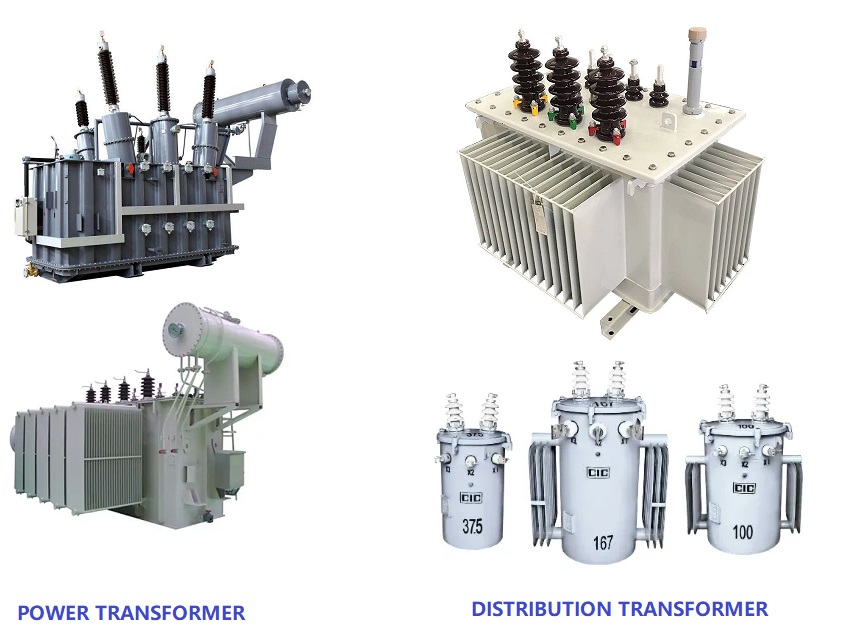

Power transformers are typically used for high voltage and high-capacity power transmission, with rated voltages reaching hundreds of kilovolts and capacities reaching hundreds of megavolt-amperes (MVA). Their high efficiency design minimizes energy loss during transmission. Due to the need to handle high voltages and large currents, power transformers have a complex structure with robust insulation and cooling systems. They are mainly used to transmit power from power plants to distribution networks or other substations, with minimal load variation, playing a role in stepping up and stepping down voltage over long distances to reduce transmission losses.

Distribution transformers are generally used for medium to low voltage applications (such as 11kV, 33kV) with smaller capacities (ranging from tens to thousands of kVA). They are designed to accommodate high load variations, suitable for supplying power to end users such as homes, shops, and factories. Compared to power transformers, distribution transformers have a simpler structure, focusing on a balance between cost and efficiency. They primarily function to deliver electricity from distribution networks to end users, commonly found in residential, commercial, and industrial areas, serving the purpose of stepping down and distributing power.

Installation, commissioning, and maintenance testing are crucial for ensuring the safe, reliable, and efficient operation of transformers. Proper installation and commissioning can prevent initial failures and ensure that the transformer meets its expected performance. Regular maintenance and testing can detect and prevent potential issues, extend the equipment's lifespan, and reduce downtime and repair costs.

These testing projects not only ensure that transformers operate safely and reliably after initial installation and commissioning but also help prevent potential issues through regular maintenance and testing, thereby extending the transformer's service life.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun