With the rapid development of the electric power industry, the quality requirements of users for electric power products are constantly increasing. In order to improve power quality and improve system stability and safety, and in accordance with the actual needs of industrial production, transformer turn ratio are increasingly important.

The transformer turn ratio is one of the important parameters of the transformer, and the change of the transformer turn ratio is closely related to the change of the transformer winding. Transformer ratio measurement that is the transformer voltage ratio measurement is to check whether the number of turns of each winding of the transformer meets the design and operation requirements, it is also called the turns ratio testing. Kingrun transformer instrument supply series transformer testers for turn ratio testing, DC winding resistance testing and oil breakdown voltage testing etc.

The ratio of high voltage to low voltage rated voltage of a transformer is often a fractional (or decimal) value, and it has to be rounded off. This inevitably causes a slight deviation between the voltage ratio and the turns ratio. In the production process, this error must be controlled so that it is within the allowable range, and the transformer ratio must be tested during the production process.

At the same time, the transformer winding is the core component of the transformer to transmit and convert electrical energy, which constitutes the electrical circuit of the transformer to input and output electrical energy. The reliability of the transformer winding is the basic factor that determines the long-term safe operation of the transformer. The reliability of the transformer winding is the basic factor that determines the long-term safe operation of the transformer.

For example, in a power system, two transformers are usually operated in parallel, and the two transformers are required to have the same phase, and the phase difference between the two transformers cannot exceed 0.5%, otherwise, a large circulation will occur between the two transformers, and the loss of the transformer will increase, which will easily lead to faults, such as winding short circuit or open circuit, winding breakdown or burning, and winding deformation. These faults will affect the reliability of the transformer windings. Deterioration of transformer ratio parameters can reflect some transformer faults. Transformer turn ratio test can detect winding interturn turn-to-turn short circuit, winding open circuit, winding breakdown and burn and other faults, and the method is simple, so the transformer will appear before operation or appear The transformer ratio needs to be checked after the fault to determine if the transformer can work normally.

Also, transformer ratio testing during transformer assembly can reveal some assembly problems. For example, measuring the transformer ratio can check whether the number of turns of the coil is correct, the quality of the soldered joints, the faults and faults of the coil short circuit, the open circuit, the tap switch, and the position of the tap changer handle and the tap changer in the case. Situation, find the tap-wire assembly problem. Before the equipment process, installation and after major repairs, the main transformer connection and the voltage transformer turn ratio of the tap must be measured to ensure that the electrical and mechanical properties of the transformer meet standards and design requirements.

When thinking about transformer testing, TTR ranks number one in the routine maintenance testing for most engineers. It provides a good starting point for transformer diagnostics, in that it tests that the transformer is doing what it is supposed to do.

FUNCTION INTRODUCTION:

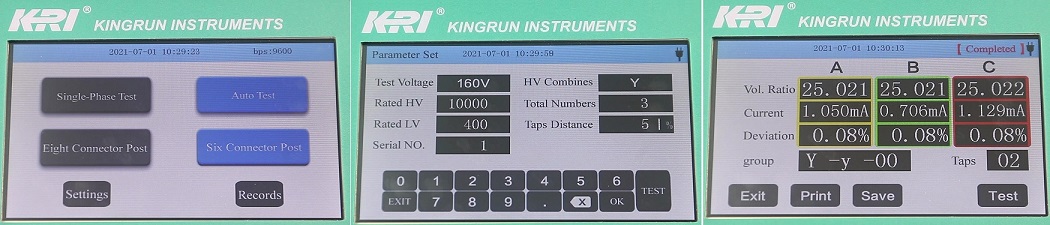

JYT-A Tester can test the transformer with neutral point by 8 testing poles, it can test the turns ratio accurately (Non conversion), it is very convenient for the manufacturer to find the fault.

●JYT-A transformer turns ratio tester (TTR tester) can cover 90% power transformers from distribution transformer to 1000kV power transformers, also can test CT, PT and transformers with Z connection.

● It has the function to measure the current.it is more sensitive to judge the inter-turns short circuit.

●The testing speed is high, it can finish the three-phase testing within 1.5 seconds by one time of wiring connection.

●The interface adopts intelligent touch mode, which is simple and convenient to operate. The circuit adopts a new generation of all digital scheme to ensure the long-term stability of the instrument.

●Without power clock and date display, the instrument can store 50 sets of data, and the data will not be lost if the power is failure.

●With large color LCD screen, the data is clear and easy to read, thermal printer printing, RS485 communication interface and U disk storage interface.

●The instrument has the protection function of misconnection of high voltage and low voltage, and has the function of transformer short-circuit and inter-turns short circuit protection. It has the protection function of power supply misconnection with AC380V.

JYT-A Transformer turns ratio tester Specification:

|

Type |

JYT-A Turns Ratio Tester |

|||||

|

Figures on display |

5 Five figure |

|||||

|

Output voltage |

AC160V |

AV10V |

Auto (DC battery) |

|||

|

Test range |

0.9 -10000 |

0.9 - 500 |

0.9 - 5000 |

|||

|

Accuracy |

<2000 |

0.1% ±2 Character |

≤150 |

0.1% ±2 Character |

≤1000 |

0.1% ±2 Character |

|

2000-10000 |

0.2% ±2 Character |

150-500 |

0.3% ±2 Character |

1000-5000 |

0.3% ±2 Character |

|

|

>2000 |

0.3% ±2Character |

|

|

|||

|

Minimum resolution |

0.0001 |

Rechargeable lithium battery |

||||

|

Power supply in operation |

AC220V±10%,50Hz±1Hz |

|||||

|

Test storied data |

50 Groups |

|||||

|

Temperature in operation |

-20~40℃ |

|||||

|

Relative humidity |

≤80%RH, No forming dew |

|||||

|

Volume/Weight |

Length 360 mm Width 280 mm Height 160 mm / 6kgs |

|||||

The 5 Most Popular transformer turn ratio testers in the World

What is the Difference between "Ratio" and "Turn Ratio" in a Transformer Testing?

How to Choose the Right Turns Ratio of CT/PT?

Why is it so Important to Test Transformer Turn Ratio?

What are the Reasons for Abnormal Voltage Output of Power Transformers?

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun