First.Precautions:

1. Strengthen the supervision of the transformer in the manufacturing , factory test, transportation and installation process, especially to prevent impurities mixed into the oil and brought into the main transformer, resulting in a rapid rise in transformer oil dielectric loss in a short period of time after the transformer is put into operation. Through the supervision of oil in the installation process of large transformers, transformer failures caused by poor oil quality of new oil can be reduced to a certain extent.

2. Since the transformer oil can reach a temperature of 60 °C ~ 80 °C in operation, the transformer oil will accelerate oxidation when in contact with air or moisture, under the action of the transformer core and copper wire as a metal catalyst. Antioxidants are constantly depleted during oil use, and the addition of T501 antioxidants can delay oil aging.

3. During the operation of the transformer, the desiccant that fails in the respirator should be replaced in time to avoid oil oxidation and deterioration. At the same time, the transformer oil should be tested in strict accordance with the pre-test procedures, and when a certain indicator is found to be unqualified, measures should be taken in time.

Second.Processing method;

1. Replace the unqualified oil.

Replacing the unqualified oil can shorten the system power outage time, just drain the old oil in the transformer, flush the transformer with the qualified oil , and then vacuum oil injection on the transformer. This treatment is more suitable for the unit not to tolerate long-term power outages; The unit has been running for a long time, the oleic acid value is high, the oil is dark yellow or brown, the phenomenon of free water or oil turbidity occurs, and it is fully degraded. However, a simple oil change is not as thorough as the "flushing" of the transformer by oil filter , and the oil change is expensive. It is not conducive to energy saving and environmental protection, and oil change treatment should not be preferred for oil exceeding the standard .

2. Regeneration treatment.

Regeneration treatment refers to the physical chemical or chemical method of removing harmful substances from the oil and restoring or improving the physical and chemical indicators of the oil. The common methods of regeneration treatment are: adsorbent method and sulfuric acid-clay method. The adsorbent method is suitable for treating oils with a light degree of deterioration; The sulfuric acid monoluton method is suitable for handling oils with a heavier degree of deterioration. The adsorbent method can be divided into contact method and percolation method, and the contact method system adopts powder adsorbent (such as clay, 801 adsorbent, etc.) and oil regeneration under stirring contact mode; The percolation method is to force the oil to be percolated and regenerated through a purifier equipped with granular admixtures (such as silicone, granular clay and activated alumina, etc.). For transformer oils with serious deterioration, the sulfuric acid monobaste method can be used for regeneration. Sulfuric acid treatment can remove a variety of aging products in the oil, and clay treatment can eliminate the defects left in the oil after acid treatment. In actual production and operation, it is often encountered that after the oil is treated by vacuum, filtration and purification, the water content of the oil is very small, and the dielectric loss factor value of the oil is high, which is because the dielectric loss factor of the oil is not only related to the water content, but also related to many factors. From the above analysis, it can be found that the reason for the increase in the dielectric loss factor of most transformer oils is due to the increase in soluble polar substances (such as sols, etc.) in the oil. For sol particles, its diameter is between 10-gm ~ 10-Tm, can pass through the filter paper, so the secondary vacuum oil filter machine to deal with its medium loss factor can not achieve the purpose, so the treatment of the oil media loss factor caused by this reason increases the problem, usually using the percolation method regeneration treatment can get good results.

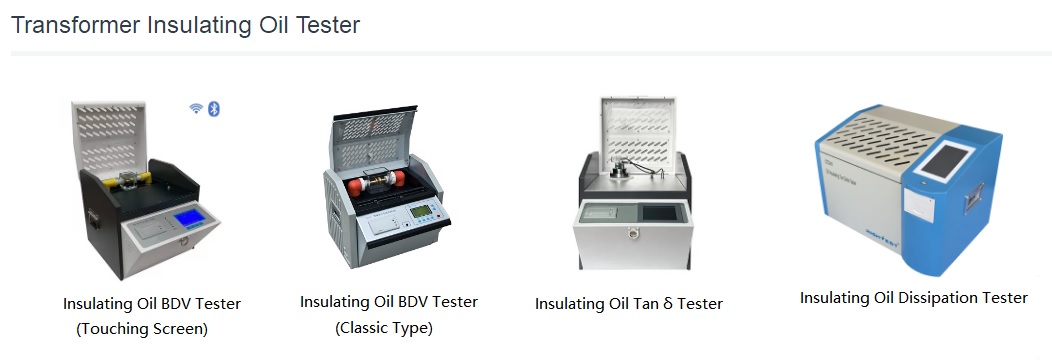

GTD-61A automatic oil Tan Delta Tester and volume resistance tester oil dielectric loss tester, Highly automatic, temperature rise, dielectric loss measurement and resistance measurement can be completed at one time.

Kingrun Transformer Instrument Co.,Ltd.