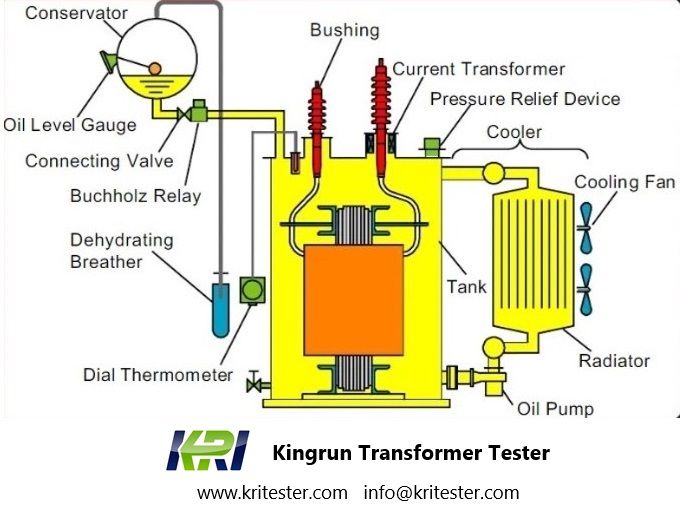

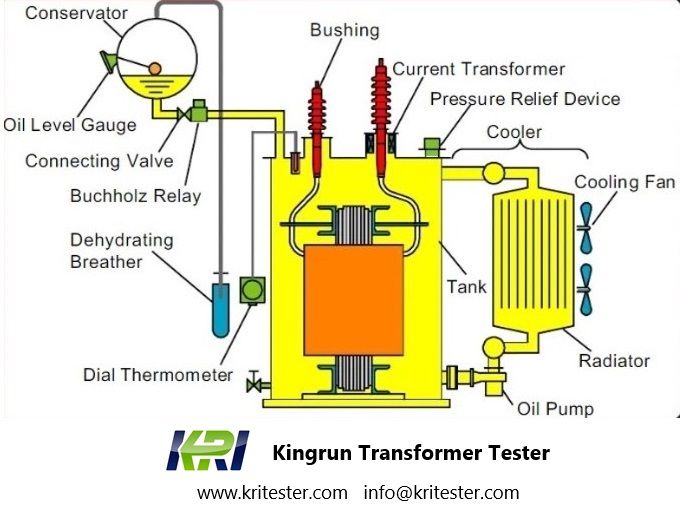

The Important Role of Each Component of the Transformer

To be an excellent doctor, you must understand the structure and function of the body, the same is true for the transformer industry, let's learn the structure of the basic transformer. This is the first step for you to become a transformer expert.

-

Conservator Tank – This is the transformer’s “oil reservoir.” When the temperature rises, the transformer oil expands and flows into the conservator tank. When it cools down, the oil contracts and returns to the main tank. This system helps maintain stable oil levels and prevents the transformer from drawing in moisture from the air.

-

Breather – Think of this as the transformer’s “air filter.” It contains silica gel, which absorbs moisture from the air before it enters the transformer. This keeps the transformer oil dry and ensures its insulating properties remain effective.

-

Buchholz Relay – The transformer’s “safety guard.” It detects internal faults, such as short circuits or overheating, by sensing gas bubbles or unusual oil flow inside the transformer. If a fault occurs, it triggers an alarm or even shuts down the transformer to prevent severe damage.

-

Radiator – The transformer’s “cooling system.” It helps dissipate heat generated during operation by allowing the transformer oil to circulate and cool down, preventing overheating and ensuring smooth performance.

-

Transformer Oil – This acts as both the transformer’s “coolant” and “insulator.” It absorbs heat from the transformer’s core and windings, helping to regulate temperature. Additionally, it provides insulation to prevent electrical discharges within the transformer.

-

Transformer Core & Winding – The transformer’s “heart and veins.” The core channels magnetic energy efficiently, while the winding (coils of wire) carries electrical current with minimal energy loss, allowing the transformer to function effectively.

-

Main Tank – The transformer’s “protective shell.” It houses all the essential internal components, including the core, windings, and oil, shielding them from external environmental conditions.

-

Explosion Vent – The transformer’s “safety valve.” If there’s excessive pressure buildup inside the transformer due to a fault, this vent releases the pressure safely to prevent explosions or serious damage.

-

Oil Gauge – The transformer’s “oil level monitor.” It allows engineers to check if there’s enough oil in the transformer to ensure proper insulation and cooling.

-

Thermometer – The transformer’s “temperature tracker.” It continuously monitors the transformer’s operating temperature to prevent overheating and potential failures.

-

Bushings – The transformer’s “insulated connectors.” They safely guide high-voltage electrical conductors through the transformer’s casing, preventing short circuits and ensuring stable electrical connections.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun