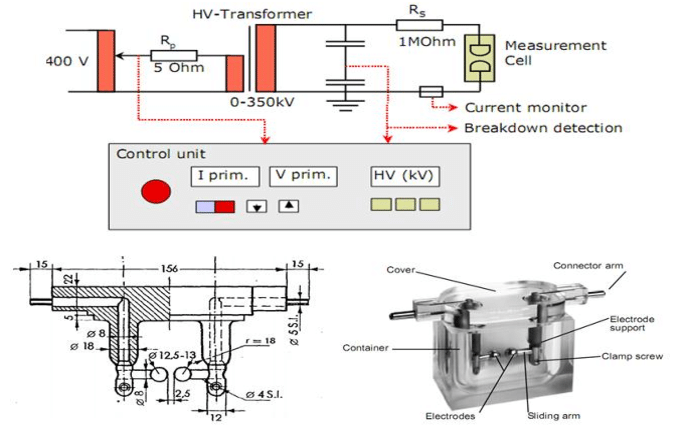

The electrode

material, electrode shape and electrode area used in measuring the breakdown strength

of the insulating oil have an influence on the insulation strength of the oil.

According to the experimental data, under the same test conditions, the order

of insulation strength of the same oil sample measured by different electrode

materials is Fe

It is common to use brass instead of copper to make the electrode, because copper tends to form an oxide film on the surface; the actual material used in the transformer is pure copper (copper) instead of brass (copper-zinc alloy). The insulation strength of transformer oil measured by standard electrodes made of these two materials, it can be seen that the measured value of the pure copper electrode is higher than the measured value of the brass electrode, and the difference between the two is not more than 10% to 15%. Therefore, it can be said that the use of a brass electrode is more stringent than that of a pure copper electrode.

In addition, the shape of the electrodes, the size of the electrodes, the distance between the electrodes, and the shape and capacity of the oil cup all have an effect on the breakdown voltage.

Studies have shown that spherical electrodes are most sensitive to oil quality; secondly, flat electrodes; and a so-called "stepped tower electrode", because the established electric field is extremely uneven, almost no oil pollution is observed. influences. If the edge of the disc electrode is not a circular arc but has sharp edges and corners, it has a great influence on the insulation strength. This is because the polar impurities in the oil will be attracted to these local high field strengths, thus reducing the oil. Uniformity. Therefore, when the edges of the electrodes are angular, the dielectric strength of the damp oil is always higher than that of the uniform electric field.

When the distance between the electrodes is small enough, the insulation strength of the oil decreases as the electrode area increases, but when the distance between the electrodes is greater than 1 mm, this dependence does not exist. The influence of the distance between the electrodes, the shape and size of the electrodes is actually the influence of the uniformity of the electric field, so the design of the electrode and the oil cup should ensure the uniformity of the electric field and the uniform distribution of the impurities in the oil, after the first breakdown of the oil. The residual carbon produced should have sufficient self-cleaning time to not affect the subsequent breakdown voltage measurement of the same oil sample.

Kingrun Transformer Instrument Co.,Ltd.