Circuit breaker timing testing is essentially a measurement of the operating speed of the breaker—specifically, the duration of its opening (trip) and closing operations. The purpose of the timing test is to determine the response time of the breaker during both opening and closing sequences.

Closing time refers to the interval from the moment a closing command is sent to the closing coil (if present) until the contacts close. These contacts may include the arcing contacts in air circuit breakers, or the main contacts in vacuum or SF6 circuit breakers.

Similarly, opening time is the time from the moment a trip signal is sent to the trip coil until these contacts are fully open.

Timing measurements are typically expressed in milliseconds (ms), though they may also be given in cycles or Hertz depending on the application. These measurements encompass the response time of the relevant coil, the mechanical operation time of the mechanism, and the moment of physical contact closure or separation.

Timing tests are critical in assessing the condition of a circuit breaker—particularly after maintenance, component replacement, factory reset adjustment, major overhaul, or corrective action beyond routine preventive maintenance.

The most common and significant issues that timing tests can help identify are those related to the operating mechanism. According to industry statistics, over 50% of serious circuit breaker failures originate from mechanical mechanism faults, with approximately 30% resulting from control or auxiliary circuit issues.

Timing and motion analysis can reveal hidden problems in a circuit breaker mechanism that may not be evident through other inspections. These tests can detect anomalies such as:

Delayed coil response

Inconsistent operation times across phases

Mechanical binding or sticking

Excessive contact bounce

Uneven motion due to worn or misaligned components

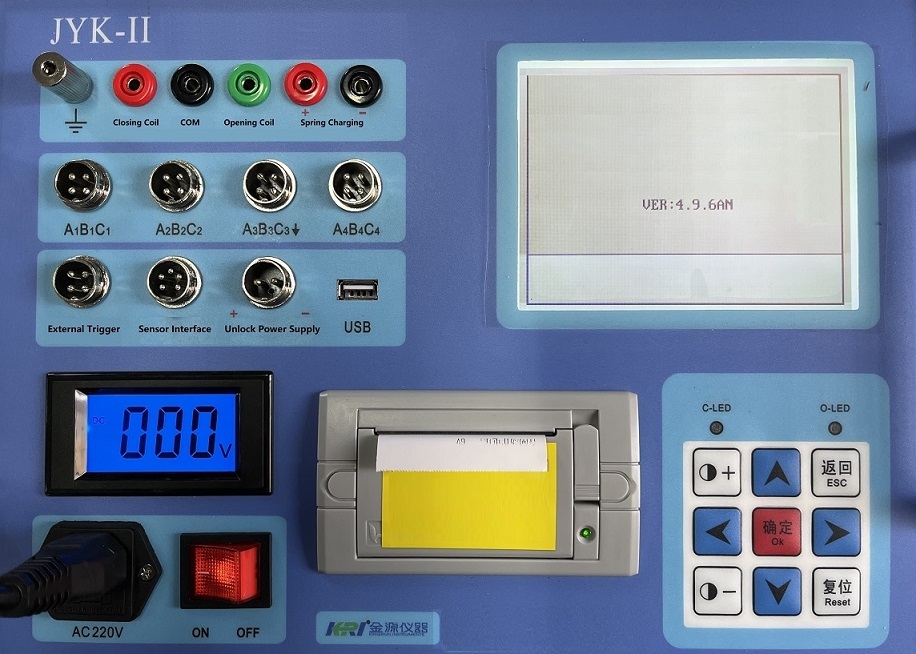

JYK-II has its own high-frequency and high-power DC adjustable power supply, which is suitable for mechanical characteristics testing of high-voltage switchgears of various voltage levels such as SF6 Vacuum circuit breaker, GIS cabinet, disconnectors etc., and can also perform low-voltage tests and reclosing tests of switches.

Wide Compatibility:

The instrument is suitable for all SF6 switchgear with metal contacts, GIS cabinets, vacuum disconnectors, oil circuit breakers, pole-mounted switches, contactors, and more.

High Sampling Frequency:

With a 100kHz sampling rate, the JYK-II ensures higher test precision and delivers more accurate and detailed measurement data.

Versatile Sensor Support:

Supports acceleration sensors, rotational speed sensors, linear travel sensors, and contact sensors. Installation is exceptionally simple and user-friendly. Capable of testing three-phase velocity, switch-on/off times, and complex sequences such as open-close, close-open, and open-close-open operations.

High-Power DC Output:

Provides up to 30A high-power DC output. The LED digital display shows real-time DC voltage, enabling clear and intuitive operation.

Flexible Trigger Modes:

Supports multiple trigger options: internal trigger, external trigger, sensor trigger, and manual trigger.

Spring Charging Output:

Offers adjustable power output for spring charging (energy storage) operations, with a maximum inrush current of 30A.

Once connected to the power source, the instrument can automatically control the motor for energy storage without the need for line reversal.

Lock Release Power Supply:

Directly replaces the on-site DC power supply to release closing and opening locks, making switch testing more convenient and efficient.

User-Friendly Display:

Equipped with a large, wide-temperature LCD screen with adjustable electronic contrast and backlight. Features a fully Chinese menu interface with intuitive prompts. Displays all measurement data and waveform diagrams with a single switching operation.

Large Data Storage and Connectivity:

The main unit can store up to 1000 sets of on-site test results. Built-in real-time clock enables automatic logging of test dates and times. Includes a USB interface for data export and firmware upgrades, and an optional RS232 port for online control.

Advanced Data Analysis:

Powerful built-in analysis functions allow in-depth evaluation of various mechanical characteristics of circuit breakers. Integrated high-speed micro printer for on-site printing of all data and waveform charts.

Multi-Purpose Durability Testing:

Supports running-in life tests for circuit breakers and isolating switches, making the instrument highly versatile and suitable for multiple applications.

|

Test Item |

Test Range |

Min.Resolution |

Accuracy |

|

Time Testing |

0 ~ 8000.0ms |

0.01ms |

≤ 0.01% rdg ± 0.1ms |

|

8000.0ms ~ 64000.0ms |

0.1ms |

≤ 0.01% rdg ± 0.1ms |

|

|

Speed Testing |

0 ~ 20.00m/s |

0.01m/s |

≤ 1% reading ± 0.01m/s |

|

Travel Testing |

0 ~ 1000.0mm |

0.1mm |

≤ 1% reading ± 0.1mm |

|

Coil Current |

Test rang: 40.00A; Resolution 0.01A |

||

|

Coil Resistance |

Test rang: 27.0Ω; Resolution 0.1Ω |

||

|

Output Power |

DC0~270V adjustable/30A; Resolution 1V, deviation ≤ 1% rdg ± 1V |

||

|

Insulation Resistance |

> 2.0MΩ |

||

|

Power Supply |

AC220V±10%, 50Hz ± 1Hz |

||

|

Volume |

L360mm * W240mm * H210mm |

||

|

Net weight |

7kg |

||

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun