Assessing the humidity in the insulation is an important factor in ensuring the reliability and service life of the transformer. The humidity in the insulating oil is constantly changing and may adversely affect the quality. In addition, most of the humidity is distributed in the insulating paper. Humidity affects the dielectric breakdown strength of solid and liquid insulating materials and affects the rate of aging of the cellulosic insulating material and the tendency of bubbles to form during overload. Ambient temperature, load, aging, leakage, and other factors can cause constant changes in humidity. Therefore, as the temperature of the transformer changes cyclically, continuous monitoring and diagnosis are required. This is more necessary for overload or peak load transformers. The total humidity in the transformer insulation system is determined by the moisture content of the cellulose and liquid. The humidity relationship between insulating paper and insulating oil depends only on the temperature. As the temperature increases, the solubility of water in the insulating oil (the water content of the solution) increases, and moisture is transferred from the insulating paper to the insulating oil. When the temperature is lowered, the process proceeds in the opposite direction, but the rate at which moisture flows from the liquid medium to the solid insulation material is rather slow. Therefore, the water content during the cooling of the insulating oil is higher than during the heating. Therefore, to accurately grasp the humidity distribution in the transformer, you must know where the equipment is in its thermal cycle. To monitor the true moisture content of the insulation paper by monitoring the moisture content in the liquid medium, the transformer must be in a relatively stable temperature state.

The relative saturation of moisture in the insulating oil needs to be standardized, because the humidity in the insulating oil is closely related to the temperature change, and there is a certain temperature gradient in the main tank of the transformer (usually the top temperature of the tank is higher than the bottom). To complete the standardization, the expert system analysis needs to infer the relative saturation percentage at the bottom. It can be obtained by using the temperature reported by the sensor and its sampling position. This analysis assumes that the transformer top temperature is 10 °C higher than the bottom temperature. If you use a position other than the top or bottom as the sampling point, you must specify the temperature deviation. Through the relative saturation of the humidity and the specific measured temperature, the expert system will use the relative saturation percentage as the calculation result of the insulation paper humidity. It must be noted that this calculation is based solely on the results of a single measurement and may not reflect the true moisture concentration of the insulating paper, especially after the transformer has just experienced severe temperature changes. If the expert system determines that the transformer is in equilibrium (the insulation paper neither releases nor absorbs the humidity), calculate the second relative saturation percentage, which is the 30-degree relative saturation percentage measurement of the zui when the transformer is in equilibrium. average of. The previously recorded temperature and changes determine whether there is a balance of judgment criteria. There are 4 available alerts. The humidity alarm is displayed with “P” as the first character. The second character is a number from 0 to 3. A P0 alarm indicates a sensor failure. A P1 alert indicates that the analysis was not performed. The P1, P2, and P3 alarms all depend on the relative saturation percentage. The conditions of the alarm: 1 is the relative saturation percentage of the insulating oil humidity ≥ 50, but <75; 2 is the relative saturation percentage of the insulating oil humidity ≥ 75.

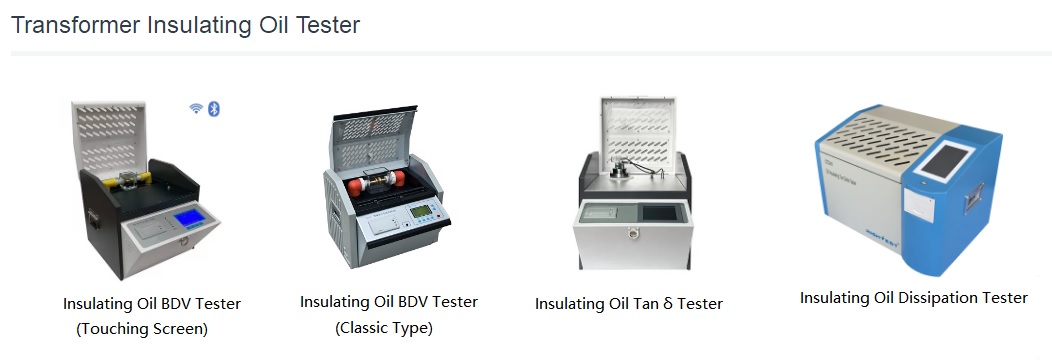

Kingrun Transformer Instrument Co.,Ltd.