What is the Breakdown Voltage/Dielectric Breakdown (BDV) of Transformer Insulating Oil?

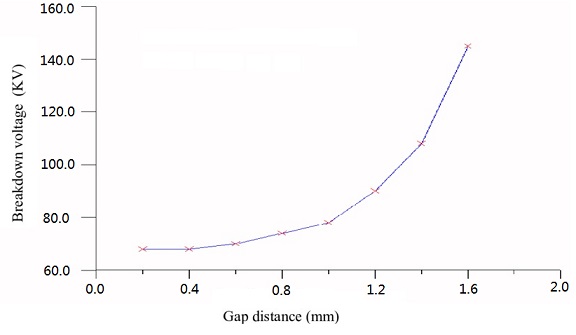

When a voltage is applied to the insulating oil, as the voltage increases, the current through the oil increases sharply, causing it to completely lose its inherent insulating properties and become a conductor. This phenomenon is called breakdown of the insulating oil. The critical voltage value at which the insulating oil breaks down is called the breakdown voltage or dielectric breakdown. The electric field strength at this time, called the dielectric strength of the oil, indicates the ability of the insulating oil to resist the electric field. The relationship between the breakdown voltage U (kV) and the dielectric strength E (kV/cm) is: E=U/d"

d"=The distance between the electrodes (cm).

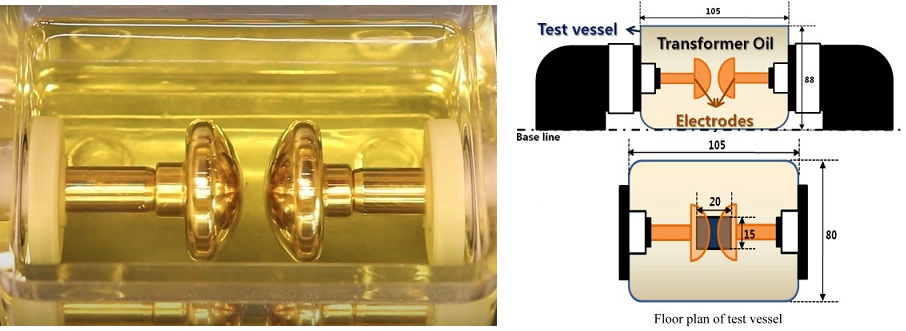

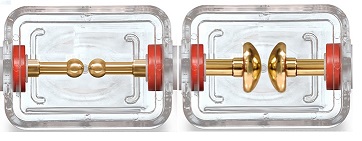

Insulating oil is a commonly used insulation, arc extinguishing and cooling medium for electrical equipment. In order to ensure its good performance during operation, it must be tested regularly, especially the oil breakdown voltage test(BDV). The breakdown voltage test of the insulating oil was carried out in a special breakdown voltage tester consisting of a porcelain or glass oil cup and two disk electrodes of 25 mm in diameter (smooth, no burn marks). During the test, the oil sample taken out was poured into the oil cup, and then placed in the electrode so that the two electrodes were separated by 2.5 mm. The test shall be carried out in a room at a temperature of 10 to 35 °C and a relative humidity of not more than 75%.

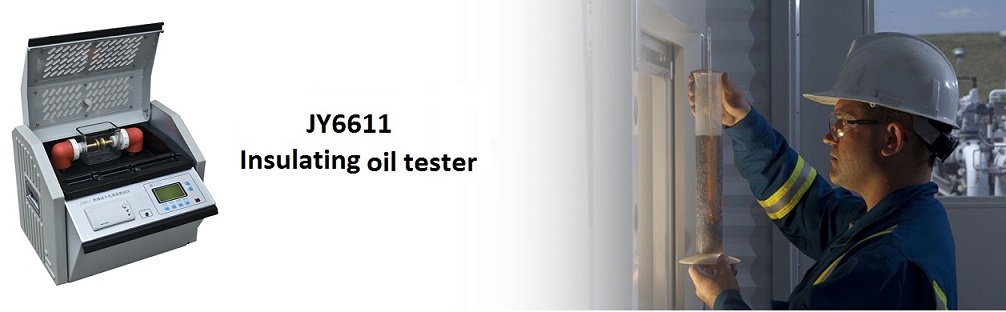

Kingrun company developed a brand-new full automatic insulating oil BDV testing kit-----JY6611,which is designed according to International Electrical Commission(IEC-156:1995). The tester’s electric system applies microcomputer control, mechanical-electrical integration and full automation, that will make sure high testing accuracy, which completely overcomes the problem of the similar product that is easy to be breakdown under high voltage.

JY6611 Insulating oil BDV tester Feature

1. Reliable testing processing:

With electromagnetism compatibility(EMC) to avoid tester crash in test process, so the oil breakdown voltage tester can work well in high-intensity electromagnetic environment,

2. 0 ~100kV Stable and Precision Test Voltage:

With 0~100kV stable output and adopts completely new breakdown voltage control technology(RBM) to make the breakdown discharge energy to the lowest,which avoid oil sample pollution during test process and make test results reliable and accurate.Also JY6611 got ILAC.MRA standard calibration certification.

3. New type oil cup:

JY6611 oil cup is made by new material with high strength and long service life to avoid fragile and leakage problem during testing.

4. Complete protection system:

JY6611 has a variety of protection devices which will make sure the safety of operator and tester itself in accident like inferior oil breakdown voltage and empty cup breakdown.

5. Multiple international testing standards

Fully automatic test sequences for 12 common test standards around the world and spot tests(Standard: ASTM D877 & ASTM D1816, IEC 60156)

6. International universal stainless steel calipers

Precise adjustment of standard electrode distances

7. Overall shielding technology

Perfect overall shielding technology can prevent all sources of electronic interference to ensure a pure test environment

8. Provide multilingual technical instructions

Provide English operation page and operation instructions in 15 languages

TECHNOLOGY SPECIFICATION:

|

Type |

JY6611 oil break down voltage(BDV) tester |

|

Output voltage |

0~80kV/100kV |

|

Minimum resolution |

0.1kV |

|

Accuracy |

Reading±0.2kV |

|

Voltage raise speed |

1 .0/2.0/3 .0kV/s for option |

|

Switch-Off time on breakdown, ms |

≤1ms |

|

Experimental times |

1~6 for option |

|

Programmed test standard |

IEC60156/ASTM D877/ASTM D1816/VDE0370 |

|

Memory for result |

500 group |

|

Volume of the oil cup |

400ml/200ml |

|

Gap between the poles |

2.5 mm (Electrode gap is adjustable) |

|

Temperature in operation |

0~40℃ |

|

Relative humidity |

≤80%RH, No forming dew |

|

Power supply in operation |

AC220V±10%, 50Hz±1% |

|

Volume / Weight |

Length 385 mm Width 300 mm Height 360 mm / 22kgs |

Following Testing Standard:

1. Dielectric breakdown (BDV) (ASTM D877 & ASTM D1816, IEC 60156)

2. Tan Delta (Dielectric Dissipation Factor (DDF)/ Power factor) (ASTM D924, IEC 60247, IEC 61620, BS 5737, JIS C2101, VDE 0380-2, IS 6262)

3. Resistivity (ASTM D1169, IEC 60247, BS 5737, JIS C2101, VDE 0380-2, IS 6103)

The specific test steps are as follows:

(1) Mix the oil sample evenly so as not to cause bubbles. Place it indoors for a few hours to bring the oil temperature as close to room temperature as possible.

(2) The insulating oil sample is connected to the test circuit and allowed to stand for 10 to 15 minutes to allow air bubbles in the oil to escape.

(3) When the power is turned on, it is pressurized at a speed of 3 kV per second, and when the oil sample is broken down (there is a significant spark discharge or the trip switch of the tester trips), the voltage value at that moment is recorded.

(4) After standing for 5 minutes, repeat the above test. Generally, each oil sample is tested 5 times, and the average voltage value is taken 5 times.

(5) If necessary, take two additional oil samples for the same test, and take the average voltage value of the three oil samples as the test result.

(6) If the voltage is added to the maximum value of the tester (such as 50 kV), the oil sample is still not broken down, and it can stay at the maximum voltage for 1 minute, and then no breakdown, the insulation oil is considered to have a good compressive strength.

Why is the transformer oil breakdown voltage test very important?

Insulating oil is widely used in liquid-filled high-voltage electrical equipment, such as power transformers, distribution transformers, transformers, bushings, oil-filled circuit breakers, oil-filled cables, oil-filled capacitors, etc. Insulating oil also acts as a coolant to dissipate electrical heat in the device. Therefore, the insulating oil should have good thermal conductivity and chemical stability at high temperatures, so before the insulating oil causes internal arcing or complete equipment failure, regular oil withstand voltage testing of transformers is an important preventive measure that will help keep the high-voltage equipment running normally, otherwise it will cause transformer failure or even casualties.

ASTM D1816, ASTM D877, and IEC 60156 are some of the popular standards that specify the dielectric strength or breakdown value and breakdown procedure for testing oil samples. The test procedure is to take a sample of insulating oil from the oil drain valve of the transformer and measure its breakdown voltage, the test voltage is applied to the electrodes immersed in the insulating oil at a constant, standard slew rate (eg 2kV/sec. The test can be carried out five to six times, and the average value of these readings can be considered as the breakdown voltage of the insulating oil under test.

The dielectric breakdown or breakdown voltage of the insulating oil should not be lower than the specified value of the recommended value. If the breakdown voltage is close to the specified limit, the sample must be subjected to further diagnostic tests such as oil resistivity and dielectric dissipation factor (tan delta) tests. As per IEEE standard, it is recommended that oil breakdown voltage tests be performed twice a year.

What is Tan δ, Or Tan Delta?

Tan Delta, also called Loss Angle or Dielectric Dissipation Factor (DDF) or Power Factor (PF) testing, is an electrical dielectric test on the insulating oil used to determine its quality. The test is performed at two temperatures. Information from each test and the results considered together may form the basis for making a judgment on whether it’s suitable for a transformer to continue in service and for determining when the replacement or regeneration of the transformer oil is needed.

1. The GTD-61A automatic Oil Tan Delta & Oil dielectric loss tester is highly automated, allowing for the measurement of temperature rise, dielectric loss, and resistance in one go.

2. The test kit adopts medium-frequency induction heating and a PID temperature control algorithm. This heating method has several advantages, including non-contact heating between the oil cup and the heating body, uniform heating, high speed, and convenient control. As a result, the temperature is strictly controlled within the preset temperature error range.

3. The GTD-61A test kit uses advanced DSP and FFT technology to ensure data stability, accuracy, and reliability.

4. The internal standard capacitor is an SF6 inflatable three-point capacitor. The dielectric loss of this capacitor is not affected by ambient temperature and humidity, so the accuracy of the instrument is still guaranteed after long-term use.

5. The large color touch screen and English operation menu make the GTD-61A test kit easy to operate.

6. The GTD-61A test kit provides tips on opening the cover after shutting off the high voltage, short-circuiting the high and low voltage electrodes of the oil cup to eliminate any hidden safety hazards, and ensuring the safety of the operator and normal operation of the equipment.

7. The test kit has a real-time clock, allowing the test date and time to be saved, displayed, and printed with the test results. The device can also display real-time monitoring of the environment.

8. The GTD-61A can automatically store and store up to 100 sets of test data.

9. The test kit has the function of calibrating the empty electrode cup. The capacitance and dielectric loss factor of the empty electrode cup are measured to judge the conditions of the empty electrode cup. The calibration data is automatically saved to facilitate accurate calculation of relative permittivity and DC resistivity.

10. The GTD-61A has a wireless transmission function, making it easy to connect with a computer for data transmission and counter charge functions.

11. The oil can be drained off automatically without being taken out, making it convenient to clean.