Transformer oil breakdown voltage (BDV) testing is a method to measure the insulation strength of transformer oil by applying high voltage using a testing device. In the early 20th century, BDV testing was a hazardous manual operation. Early equipment used large, exposed high-voltage step-up transformers connected to a simple spark gap immersed in an oil cup.There were no automatic control devices; operators had to manually turn heavy rheostats or "variable transformers" to increase the voltage until a visible and audible arc broke down the oil layer. These devices were housed in thick cast iron or wooden enclosures, lacking the safety interlocks that are common today.

By the 1950s and 1960s, electrode shapes (such as VDE or ASTM spherical electrodes) were standardized in the industry. Testers became more portable, integrating the transformer and oil cup into a "briefcase" design, but still relied on analog meters and manual timing.The digital era transformed BDV testers into "set-and-forget" devices. Modern testers use microprocessors to precisely control the voltage rise rate, detect breakdowns in microseconds, and automatically stir the oil between tests. Today's devices are extremely lightweight and come equipped with built-in printers and Bluetooth functionality.

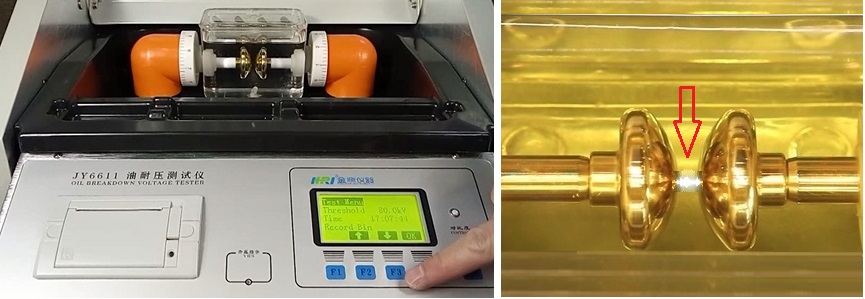

The JY6611 Insulating oil breakdown voltage tester adopts a completely new electromagnetic compatibility (EMC) concept designed to prevent tester crashes during testing and ensures it can operate effectively in high magnetic fields.

The JY6611 also uses advanced voltage breakdown control technology, which keeps breakdown energy at a very low level. This prevents contamination of the oil sample during testing and ensures the test results are accurate and reliable.

The unique advantage of this tester lies in its built-in electronic boost system. The voltage regulation power supply uses an electronic inverter sine wave generator, providing accurate voltage output with high waveform quality. It is not affected by grid voltage fluctuations or waveform distortion, making the test data more accurate and efficient. The built-in advanced insulating material and heat dissipation system ensure that the step-up transformer remains stable and reliable, allowing the tester to withstand long-term high-voltage breakdown tests. This design protects operator safety and extends the service life of the tester

JY6611 Insulating oil BDV tester Feature:

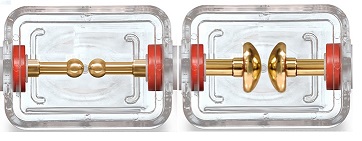

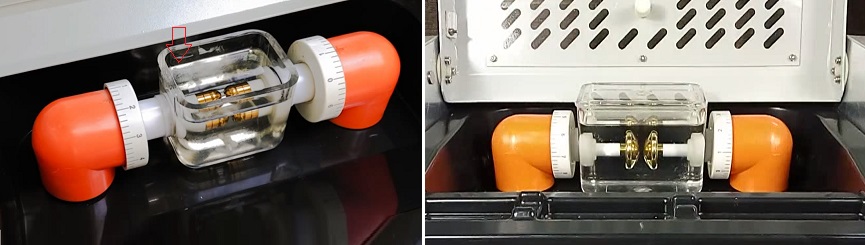

1. Reliable testing processing:JY6611 oil cup is made by new material with high strength and long service life to avoid fragile and leakage problem during testing.

4. Complete protection system:

JY6611 has a variety of protection devices which will make sure the safety of operator and tester itself in accident like inferior oil breakdown voltage and empty cup breakdown.

5. Multiple international testing standards

Fully automatic test sequences for 12 common test standards around the world and spot tests(Standard: ASTM D877 & ASTM D1816, IEC 60156)

6. International universal stainless steel calipers

Precise adjustment of standard electrode distances

7. Overall shielding technology

Perfect overall shielding technology can prevent all sources of electronic interference to ensure a pure test environment

8. Provide multilingual technical instructions

Provide English operation page and operation instructions in 15 languages

TECHNOLOGY SPECIFICATION:

Model

JY6611 Oil Breakdown Voltage (BDV) tester

Output Voltage Range

0~80 kV / 100 kV

Voltage Resolution

0.1 kV

Measurement Accuracy

±2% of reading ±0.2 kV

Voltage Ramp Rate

1.0 /2.0 /3.0 kV/s (selectable)

Trip Time at Breakdown, ms

≤ 1ms

Test Repetitions

1~6 (selectable)

Applicable Standard

IEC 60156 / ASTM D877 / ASTM D1816 / VDE0370

Result Storage Capacity

30 groups

Oil Cup Capacity

400ml / 200ml

Electrode Gap

2.5 mm (adjustable)

Operation Temperature

0℃~40℃

Operating Relative Humidity

≤ 80%RH, No Condensation

Power Supply Requirement

AC220V±10%, 50Hz±1%

Dimensions / Weight

Length 385 mm Width 300 mm Height 360 mm / 22kgs

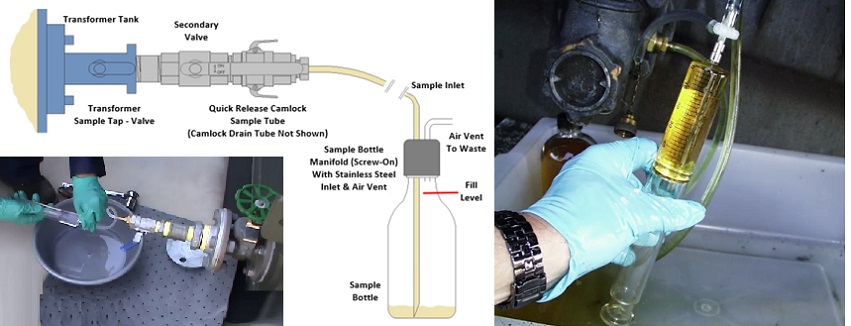

1. Collect the oil sample using a clean and dry sampling bottle at the transformer’s sampling valve.

2.Clean and dry the oil test cup, standard electrode gauge, stirring glass rod, and the glass cover plate.Ensure that no moisture, fibers, or residue remain on any component.

The sampling valve shall be cleaned, dried, and flushed before sampling.The insulating oil should be cooled and stabilized at 27°C ± 2°C prior to testing.

3. Rinse the test cup three times with the sample oil.

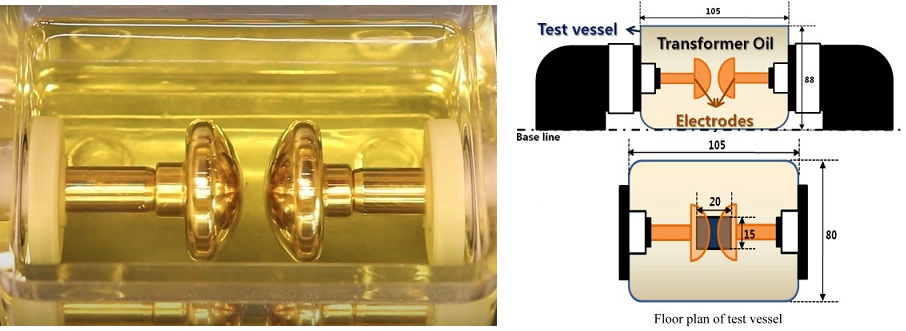

Use the electrode gauge to adjust the electrode gap to 2.5 mm ± 0.1 mm (per IEC 60156 / ASTM D1816).

Slowly pour the sample oil along the stirring glass rod to avoid air entrapment.Fill the cup until the oil level is at least 10 mm above the electrodes

Cover the cup with the glass plate and allow it to stand for 10–15 minutes to release any entrained air bubbles.

4. then slowly inject the test oil into the oil cup along the stirring glass rod until it is ≥10 mm above the electrode, then cover the glass cover

and let it stand still for 15 minutes to make the air bubbles in the oil overflow.

5. Run the BDV test:

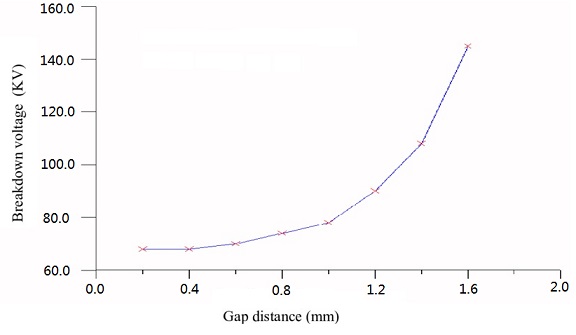

Power on the BDV tester and apply voltage continuously and uniformly at a rate of 3–5 kV/s.

Increase the voltage until breakdown occurs between the electrodes, and the tester trips (overcurrent or breakdown detection circuit activates).

6. The tester will repeat the breakdown sequence and perform a total of six breakdown tests with the same sample.

(Some countries and customers prefer to discard the first breakdown value, considering it a conditioning cycle, as the initial breakdown helps

remove fine particles on the electrode surface and release nearby air bubbles, resulting in a more uniform local electric field. In our procedure,

however, we use all six breakdown values.)

Calculate the average of the remaining five breakdown values as the final BDV result(see the table below)

The test oil sample is laboratory-grade oil and is for reference only.

7. Evaluate the result:

If the insulating oil BDV value is ≥ 30 kV (for a 2.5 mm IEC test cell), the transformer oil is considered to be in good dielectric condition.

Lower values indicate contamination or deterioration and may require oil filtration or replacement.

|

Oil Sample No. |

Sample Test No. |

BDV Value (KV) |

Average BDV (KV) |

Oil BDV Value(KV) |

|

1 |

1 |

27.9 |

(27.9+28.4+25.4+23.7+22.3+33.6)/6 |

26.89 |

|

2 |

28.4 |

|||

|

3 |

25.4 |

|||

|

4 |

23.7 |

|||

|

5 |

22.3 |

|||

|

6 |

33.6 |

The test oil sample is laboratory-grade oil and is for reference only

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun

transformer oilltage breakdo