Why Winding Resistance Testing of Transformers is Needed?

The winding resistance of a transformer refers to the DC resistance value of each phase winding. The purpose of measuring the winding resistance is as follows:

1. To check the welding quality of the wires and leads inside the transformer windings.

2. To check whether the winding or lead wire is broken.

3. To check the correctness of the parallel branches, and whether there are any disconnections in the winding formed by multiple parallel wires.

4. To check whether there is a short circuit between the layers and turns of the transformer.

If there is a phase-to-phase short circuit inside the transformer, the short-circuit current value will be very high, and it can easily burn out the transformer. By measuring the DC resistance of each phase and comparing the three-phase winding resistance values, it is easy to determine whether there is an inter-turn short circuit. If the resistance values vary greatly, the possibility of an inter-turn short-circuit fault is very high.

KRI 9310 Winding Resistance Tester Features

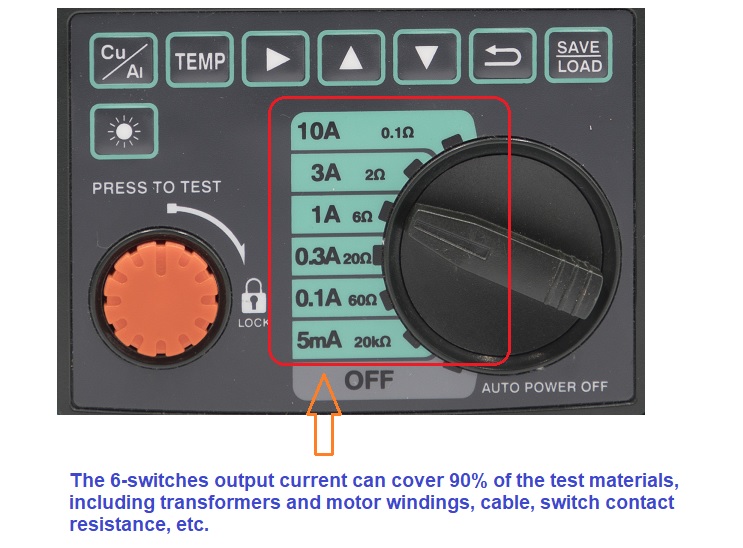

The KRI 9310 utilizes the ARM (Advanced RISC Machines; USA) high-precision multi-core CPU, offering stable performance and high computational accuracy, which also effectively eliminates the influence of the test line resistance on the results. The KRI 9310 increases the current to 10A, allowing it to test extremely low resistance values down to 0.01 Ω (such as amorphous alloy, copper-nickel, nickel-chromium-iron, iron-chromium-aluminum, etc.). For tested objects with high resistance values (such as CT/PT), the instrument can extend the range to 20 kΩ. This wide resistance testing range enables the KRI 9310 to cover 80% of power transformer products on the market, as well as switchgear bus-bar cables, etc. The tester is powered by a built-in rechargeable lithium battery, which allows for testing hundreds of transformers on a single charge.

KRI 9310 DC winding resistance tester Application Test Objects:

TECHNICAL INTRODUCTION:

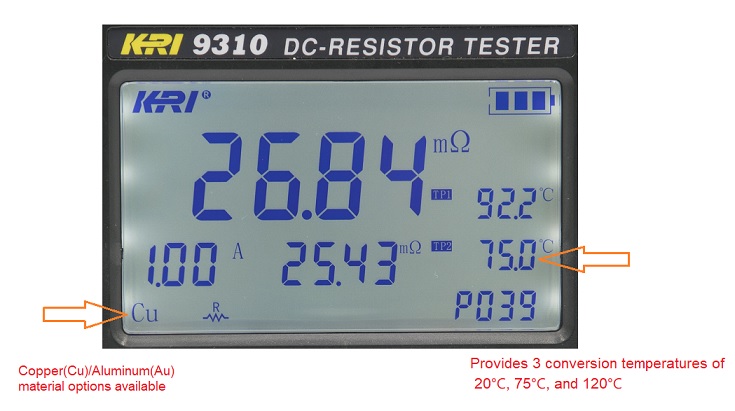

The KRI 9310 is equipped with a temperature conversion function. By selecting the test sample material (copper/aluminum) and temperature from the tester, the instrument can automatically convert the resistance values to those under the standard temperature (20°C, 75°C, 120°C). The KRI 9310 also features a data storage function, allowing 500 groups of experimental data to be stored within the instrument. Additionally, the KRI 9310 has a USB interface, enabling data to be downloaded to a flash drive.

TECHNOLOGY SPECIFICATION:

|

Tester type |

KRI 9310 |

|||||

|

Scope of application |

10A |

3A |

1A |

0.3A |

0.1A |

5mA |

|

Test range |

0Ω~0.1Ω |

0.01Ω~2Ω |

0.03Ω~6Ω |

0.1Ω~20Ω |

0.3Ω~60Ω |

30Ω~20kΩ |

|

Accuracy |

0.1%±0.5μΩ |

|||||

|

Minimum resolution |

0.1μΩ |

|||||

|

Built-in battery |

11.1V ; Capacity:4500mmAh |

|||||

|

Standard conversion temp. |

20℃/75℃/120℃ |

|||||

|

Temperature test range |

-99.9~199.9℃ ; Accuracy: ±0.5% (JYR9311 only) |

|||||

|

Volume / weight |

Length 155 mm Width 210 mm Height 68 mm /1.66 kg |

|||||

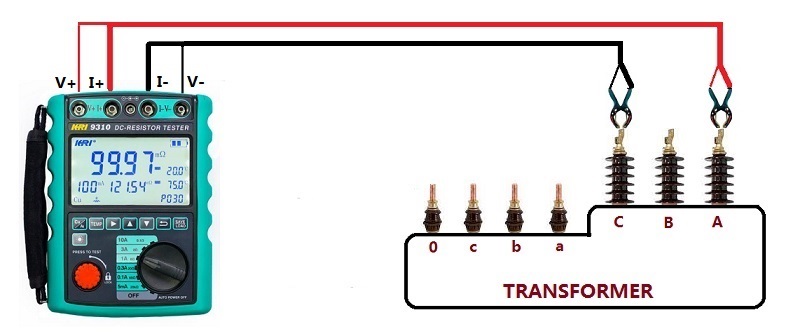

KRI 9310 Transformer Winding Resistance Testing Connection:

Testing sites of JYR-9310 DC winding resistance tester: