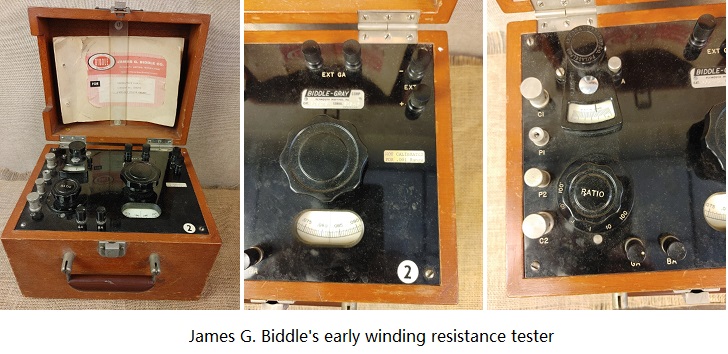

In the early 20th century, transformer DC resistance testing primarily relied on basic bridge circuits. Due to the very low resistance and high inductance of transformer windings, the Kelvin double bridge became the standard method for measuring sub-ohm resistances and eliminating the effects of lead resistance, these early "testers" were not single devices but assemblies made of brass and wooden components, including sensitive galvanometers, large-capacity batteries, and manual sliding resistors, operators had to wait several minutes until the transformer core's large inductance saturated before obtaining stable readings. By the mid-20th century, these components were integrated into portable wooden box bridge devices. While more convenient, they still required manual balancing and complex temperature correction. The digital revolution of the 1980s introduced the "current-source" method, utilizing stable DC power supplies and microprocessors to calculate resistance through Ohm's Law (R = V/I). Modern testers are now equipped with high-speed discharge circuits that safely dissipate stored magnetic energy, along with automatic temperature compensation and multi-phase testing functions, transforming the cumbersome manual process into a quick one-button diagnostic.

Why DC Winding Resistance Testing of Transformers is Needed?

Why DC Winding Resistance Testing of Transformers is Needed?

DC winding resistance testing is considered an essential routine screening tool. It helps identify issues such as loose, defective, or incorrect connections, which lead to transformer failures each year, making it a failure category of its own. Winding resistance testing can also reveal problems with transformer tap-changers, on-load tap changers (OLTC), and de-energized tap changers (DETC)—key components that frequently fail in transformers, and according to some statistics, they are among the leading causes of transformer failures.

JYR-05/10C DC Winding Resistance Tester Function Introduction:

1.The testing range is 0Ω to 100kΩ, with an automatic temperature switching function.

2.The maximum output current is 5A/10A, which can test all inductive DC resistances below 110kV.

3.The maximum output voltage is 24V, ensuring high testing speed.

4.Equipped with both DC and AC switches, it is suitable for all inductive load measurements, such as transformers, PT, CT, etc.

5.Equipped with a permanent calendar, it can store 100 sets of data, and the automatic temperature conversion function ensures data is not lost during power failure.

6.With a large color touch screen, the data is clear and easy to read.

7.Equipped with an RS485 communication interface for PC control.

8.Equipped with a USB storage interface for exporting data and a thermal printer for printing.

9.Includes an anti-arcing protection function for inductively tested products.

10.Includes an AC380V misconnection protection function to avoid damage from incorrect operation.

11.Includes a discharge alarm with sound and clear discharge indication.

12.Features an internal high-efficiency power source with no fan, preventing dust ingress and increasing lifetime.

TECHNOLOGY SPECIFICATION:

Deployment

10C

05C

Output current

10A,3A,1A, 300mA,100mA,20mA; Auto

5A、2.5A、100mA、 <10mA

Test range

0~100kΩ

0~20kΩ

Accuracy

0.2%±1μΩ

0.2%±2μΩ

Minimum resolution

0.1μΩ

Power supply in operation

AC220V±10%, 50Hz±1Hz

Temperature in operation

-20~40℃

Relative humidity

≤80%RH, No forming dew

Volume

Length 335mm Width 235mm Height 260mm

Net weight

7 kg

Application range

Suitable for all levels of inductive resistance measurements of 132kV and below

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun