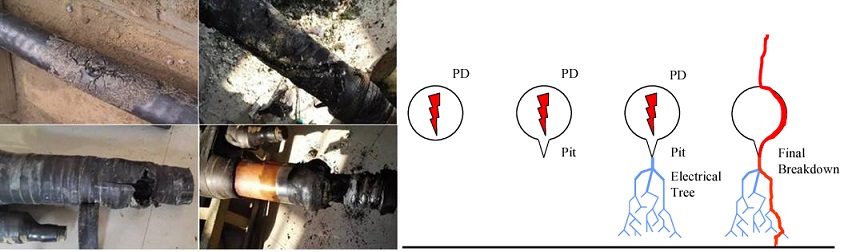

Infrared Thermography (IRT) and Partial Discharge (PD) testing are two widely adopted condition monitoring techniques in modern power systems, each with distinct applications and technical strengths. IRT detects surface temperature anomalies to identify potential faults caused by increased electrical resistance, such as loose connections, overloads, or deteriorated contacts. Based on passive thermal radiation measurement, IRT is simple to operate, allows for non-intrusive and live inspections, and is particularly effective for components like switchgear, busbars, and cable terminations. However, it has notable limitations: it can only detect faults that produce significant heat and cannot identify early-stage insulation degradation or internal defects. The results are also influenced by ambient temperature, surface emissivity settings, and operator experience. In contrast, PD testing detects small electrical discharges occurring within or on the surface of insulation systems. These discharges often indicate the onset of insulation breakdown, such as voids, cracks, surface contamination, or moisture ingress, allowing for much earlier detection of critical insulation failures.

In summary, IRT is well-suited for identifying resistive faults and surface heating, while PD testing is more effective at detecting internal insulation degradation at an early stage. Integrating both methods enables a comprehensive asset monitoring strategy, combining surface thermal detection with internal dielectric diagnostics. Industry standards recommend joint application, and the reliability of the results depends heavily on the competency of the operators. Certified training (e.g., FLIR Level I/II for thermography or PD specialist training from EA Technology) is strongly recommended. By selecting the appropriate method based on asset type, voltage level, and environmental conditions, utilities and asset managers can significantly improve system reliability and reduce the risk of unplanned outages and catastrophic failures.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun