Insulating oil is widely used in high-voltage electrical equipment such as transformers, oil circuit breakers, oil-filled cables, power capacitors and bushings. Its functions are as follows:

1. Insulation. Impregnates and protects solid insulation such as transformers, cables, capacitors, etc., fills the air bubbles in the insulation, prevents the intrusion of air or moisture, and ensures reliable insulation.

2. Cooling effect. It has a good cooling effect on electrical equipment such as transformers.

3. Arc extinguishing effect. The insulating oil in the oil circuit breaker not only has the function of insulation, but also has the function of extinguishing the arc, so that the circuit breaker can cut off the arc quickly and reliably.

During the operation of the transformer, the insulating oil will gradually change its performance due to the action of high oxygen humidity, high temperature, sunlight, strong electric field and impurities, so that it cannot fully exert its insulating effect. Therefore, it is necessary to regularly conduct relevant tests on insulating oil to identify whether its performance has deteriorated. Among them, the oil breakdown voltage (BDV) test is a very important test item.

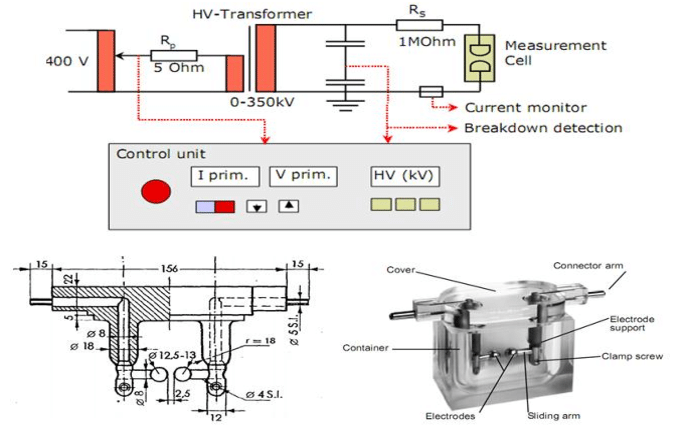

Since the oil breakdown voltage test conditions are strict, the withstand voltage test of the insulating oil is carried out in a special breakdown voltage tester.

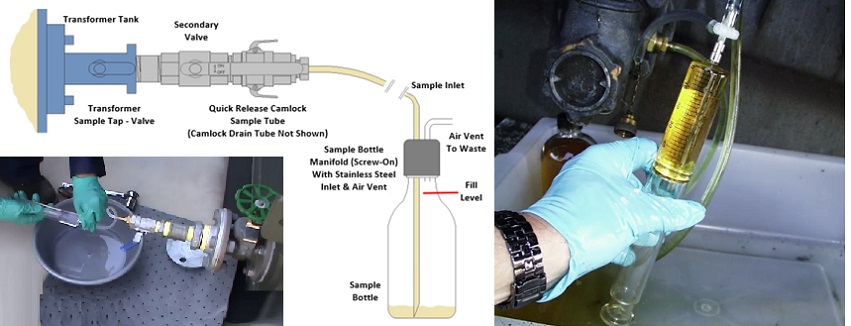

1. Collect the oil sample using a clean and dry sampling bottle at the transformer’s sampling valve.

2.Clean and dry the oil test cup, standard electrode gauge, stirring glass rod, and the glass cover plate.Ensure that no moisture, fibers, or

residue remain on any component. The sampling valve shall be cleaned, dried, and flushed before sampling.The insulating oil should be

cooled and stabilized at 27°C ± 2°C prior to testing.

3. Rinse the test cup three times with the sample oil.

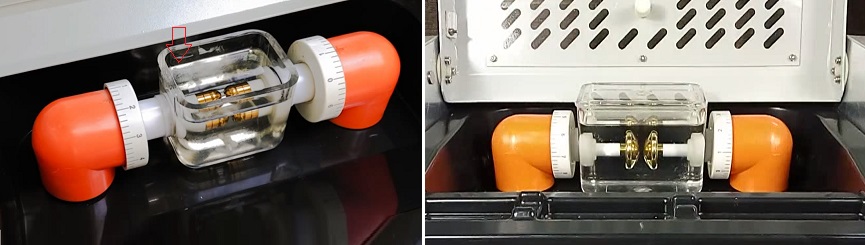

Use the electrode gauge to adjust the electrode gap to 2.5 mm ± 0.1 mm (per IEC 60156 / ASTM D1816).Slowly pour the sample oil along the

stirring glass rod to avoid air entrapment.Fill the cup until the oil level is at least 10 mm above the electrodes. Cover the cup with the glass plate

and allow it to stand for 10–15 minutes to release any entrained air bubbles.

4. then slowly inject the test oil into the oil cup along the stirring glass rod until it is ≥10 mm above the electrode, then cover the glass cover

and let it stand still for 15 minutes to make the air bubbles in the oil overflow.

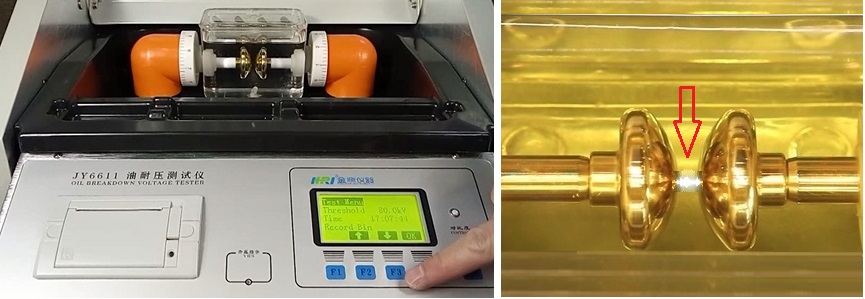

5. Run the BDV test:

Power on the BDV tester and apply voltage continuously and uniformly at a rate of 3–5 kV/s.

Increase the voltage until breakdown occurs between the electrodes, and the tester trips (overcurrent or breakdown detection circuit activates).

6. The tester will repeat the breakdown sequence and perform a total of six breakdown tests with the same sample.

(Some countries and customers prefer to discard the first breakdown value, considering it a conditioning cycle, as the initial breakdown helps

remove fine particles on the electrode surface and release nearby air bubbles, resulting in a more uniform local electric field. In our procedure,

however, we use all six breakdown values.)

Calculate the average of the remaining five breakdown values as the final BDV result(see the table below)

The test oil sample is laboratory-grade oil and is for reference only.

7. Evaluate the result:

If the insulating oil BDV value is ≥ 30 kV (for a 2.5 mm IEC test cell), the transformer oil is considered to be in good dielectric condition.

Lower values indicate contamination or deterioration and may require oil filtration or replacement.

|

Oil Sample No. |

Sample Test No. |

BDV Value (KV) |

Average BDV (KV) |

Oil BDV Value(KV) |

|

1 |

1 |

27.9 |

(27.9+28.4+25.4+23.7+22.3+33.6)/6 |

26.89 |

|

2 |

28.4 |

|||

|

3 |

25.4 |

|||

|

4 |

23.7 |

|||

|

5 |

22.3 |

|||

|

6 |

33.6 |

Kingrun Transformer Instrument Co.,Ltd.

transformer oilltage breakdo

Please Check More Transformer/Substation Testers from Kingrun:

What are the Acceptance Testing Items after Transformer Installation, Commissioning and Repair?

What is the Difference Between Flash Point and Ignition Point of Transformer Oil?

Key Points to Note in Transformer Oil Breakdown Voltage (BDV) testing

High Precision Insulating Oil Tester--BDV & Tan Delta

How to Judge Transformer Fault Through Transformer Oil