Transformer insulating oil acts as insulation and cooling and must have a certain electrical insulation strength during operation. In order to ensure the safe and reliable operation of the transformer, in addition to protecting the operating transformer insulating oil to prevent premature aging, the oil sample test should be taken regularly to understand the state of the oil quality during operation. For newly installed transformers, the insulating oil sample test should also be taken before the new operation. The transformer insulating oil breakdown voltage test is one of the main items in the transformer oil test. This article only talks about some of the problems in the breakdown voltage test.

I. Influence of Test Environment on Breakdown Voltage Processing

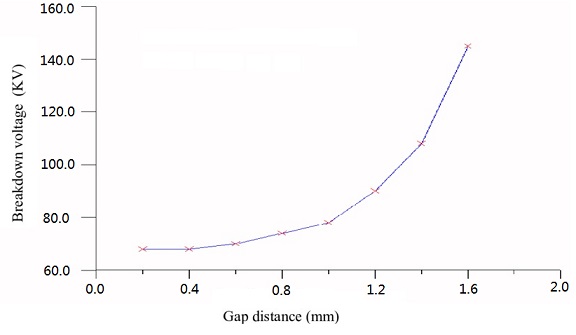

The insulation strength (also known as breakdown voltage) of transformer insulating oil is related to the weather and the atmospheric pressure of the test environment. It is related to the atmospheric pressure of the test environment below 25 °C. The water is divided into an emulsified state, so the value of the breakdown voltage of the insulating oil decreases as the temperature decreases.

However, when the temperature is lower than 0°C, the breakdown voltage of the oil will increase as all the water in the oil decomposes into ice. Generally, the breakdown voltage is the highest when the oil temperature is 65 to 80 ° C. This is because the moisture component of the oil is dissolved in the insulating oil. If the temperature exceeds 80°C, the breakdown voltage begins to decrease again. This is because the energy of the polar molecules such as pollution in the suspension of the oil is accelerated, thereby increasing the probability of breakdown in the oil. In addition, the breakdown voltage of the oil is also related to the pressure of the test environment, the pressure increases, and the insulation strength increases.

II. the normal operation during the testing

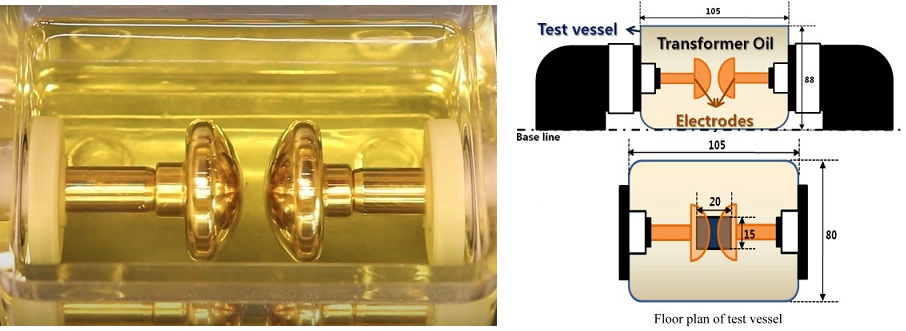

When doing the transformer oil breakdown voltage test, a cup of insulating oil should be subjected to breakdown voltage several times, the longer the interval is, the higher the breakdown voltage is, the shorter the interval is, the lower the breakdown voltage is, this is the general test equipment. When the oil breaks down, the arc formed in the electrode gap causes the free charged particles, bubbles and carbon particles in the oil to remain in the gap of the electrode, and the test is repeated at a short interval, when this part of the stain is easy to form a bridge, the value is low, and the more the interval time K, the part of the dirt will gradually disperse away from the electrode gap due to gravity, so the test value increases with the interval and the breakdown voltage the value is increased.

The normal operation should be: after the test oil is full, let it stand for 10 minutes and then carry out the ascension test. After each breakdown, use the prepared clean glass rod to make a few times between the electrodes or gently vibrate the oil cup to achieve damage., the newly formed bridge between the electrodes can be left for 5 minutes for the next test.

It is recommended to connect a current limiting resistor in series with the high voltage side of the transformer to limit the current during the gap breakdown. This shortens the time between two intervals and gives an accurate breakdown voltage value.

III. Analysis of the variation of breakdown voltage value

In the test when the breakdown voltage of the transformer oil is tested, generally a cup of insulating oil is tested 5 times, and the average value is taken.

1. The first time the breakdown voltage is extremely low: the first test may have some external factors caused by the oil injection into the oil cup or the surface of the oil cup electrode before the insulating oil injection, so that the first value It is low, so it is necessary to carry out the sixth test and take the average of 2 to 6 times.

2.5 times the average value of the breakdown voltage is gradually increased: it is usually found in oil samples that have not been cleaned or treated thoroughly enough to absorb moisture. This is due to the improved moisture level of the oil after the oil is penetrated. .

3.5 times the breakdown voltage value is gradually reduced: the general mountain is now tested in a purer insulating oil, because the amount of free-charged electron particles, bubbles and carbon chips generated successively increases, which damages the insulation properties of the oil.

4. The breakdown voltage value is low in the middle and low in the middle: this is normal.

At present, the transformer oil supplied by individual refineries often has a phenomenon that the breakdown voltage may be 20-30% different from the previous time, which is called the dispersion of the breakdown voltage. This is not necessarily a defect of the test instrument and method, but Determined by the nature of the oil sample. This is improved by improving the quality of the oil sample.

JY6611 Insulating Oil Breakdown Voltage Tester

Using microprocessors automatically completes the boosting, maintaining, stirring, static, calculating, printing and other operations, and can carry out the oil cycle withstand test within the range of 0 to 80kV.

JY6611 Transformer Oil Breakdown Voltage (BDV) Tester Demo Video:

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun