Accurate measurement of contact resistance is crucial for assessing the performance and reliability of vacuum circuit breakers.Elevated contact resistance readings can indicate underlying issues that may compromise the breaker’s functionality.Understanding the factors contributing to increased contact resistance is essential for effective troubleshooting and maintenance, ensuring operational safety and extending the service life of high-voltage equipment

1. Instrumentation Factors:

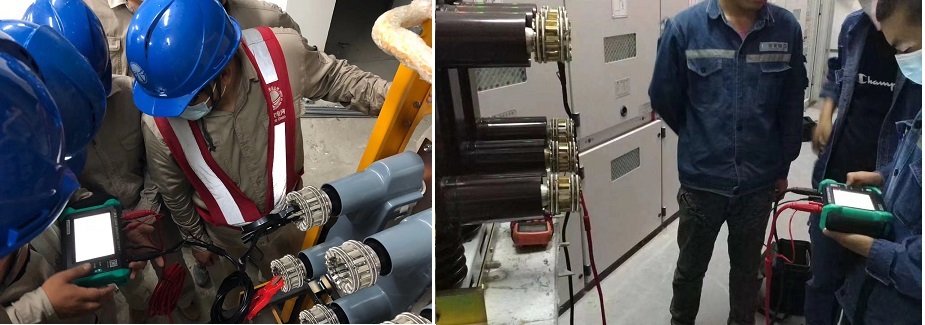

Accuracy of the Tester: Ensure the Contact Resistance Tester is calibrated and functioning correctly.

Connection Integrity: Check for loose or oxidized terminals on the tester, as these can introduce additional resistance.

Correct Wiring: Verify that the voltage input line is not connected to the current output line.

Clamping Quality: Ensure the current clamp makes reliable contact with the test object to avoid excessive resistance.

Adequate Testing Duration: Conduct tests for the time specified by national standards to obtain accurate readings.

2. Vacuum Circuit Breaker–Related Factors:

Grounding Issues: If both ends of the vacuum circuit breaker are grounded, a parallel circuit is formed, leading to inaccurate resistance measurements.

Contact Oxidation: Oxidation of dynamic and static contacts increases resistance and can lead to overheating.

Mechanical Impurities: Residual particles or carbides between contacts can impede current flow and elevate resistance.

Contact Degradation: Issues like mechanical jams, contact spring failures, or broken contact bullets can cause voltage drops and increased resistance.

Reduced Contact Area: Improper adjustment or displacement during operation can decrease the effective contact area, raising resistance.

Conclusion :

Elevated contact resistance readings during testing can stem from both instrumentation and vacuum circuit breaker–related factors.Addressing these issues involves ensuring the accuracy and integrity of the testing equipment, as well as maintaining the vacuum circuit breaker in optimal condition.Regular maintenance, proper grounding, and timely replacement of worn components are essential practices to minimize contact resistance and ensure reliable operation.By proactively managing these factors, the risk of equipment failure due to excessive contact resistance can be significantly reduced, leading to enhanced safety and performance in high-voltage electrical systems.

Other Related Articles:

Why Does the Contact Resistance Testing Need 100A or Higher?

Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

How to measure the contact resistance without changing the circuit?

How to Correctly Test the Contact Resistance of HV Switchgear or Circuit Breaker?

Why Does Excessive Contact Resistance Occur In Electrical Secondary Circuits?

What is the Testing Checklist for 110kV/220kV Substation Acceptance and Maintenance Testing?

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun