The development of Contact Resistance Testers (Micro-ohmmeters) was driven by the need to ensure the reliability of high-current connections in power grids, such as circuit breakers and busbars.

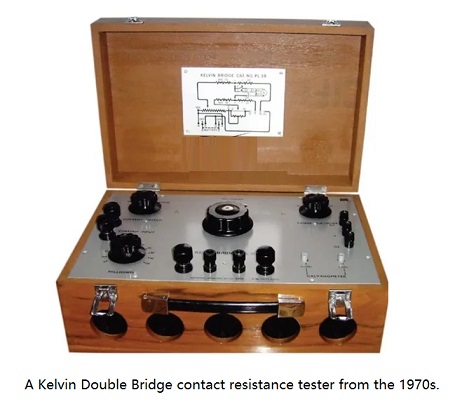

In the early 20th century, measuring micro-ohm resistance was a laboratory feat. The Kelvin Double Bridge was the primary method used to overcome the interference of test lead resistance. These early instruments were expansive, manual setups featuring mahogany boxes, brass terminals, and highly sensitive mirror galvanometers. Measuring a single contact required precise manual balancing and stable DC sources, often provided by massive lead-acid batteries.

By the 1960s and 70s, technology shifted toward the Four-Wire (Kelvin) Sensing method integrated into portable industrial units. These used analog meters and heavy internal transformers to generate the high DC currents (often 100A or more) required to "burn through" surface oxidation for an accurate reading.

The modern era introduced Switch Mode Power Supply (SMPS) technology, making testers lightweight and battery-operated. Today’s digital contact resistance testers are microprocessor-controlled, offering automatic current regulation, high-speed data logging, and sub-micro-ohm precision.

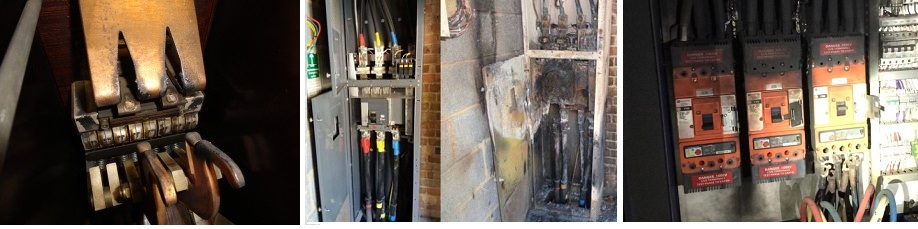

As a high current passes through a pair of mechanically independent metallic contacts, the contact resistance must be as low as possible. Increasing the contact resistance of the contact often causes a large voltage drop on the contact, which reduces the input power of the load equipment. If the contact resistance of one or two contacts becomes large, the three-phase voltage of the load equipment will be unbalanced, causing phase loss operation.

If the contact resistance is too large,great heat will be generated, which can make the metal discolor or even melt, damage the insulation layer, cause equipment failure, and even fire of flammable materials.So we need to make regular measurements of the dynamic and static contact resistance of the contacts by contact resistance tester to ensure that the contacts being tested are in good contact.

High contact resistance will lead to equipments burn out.

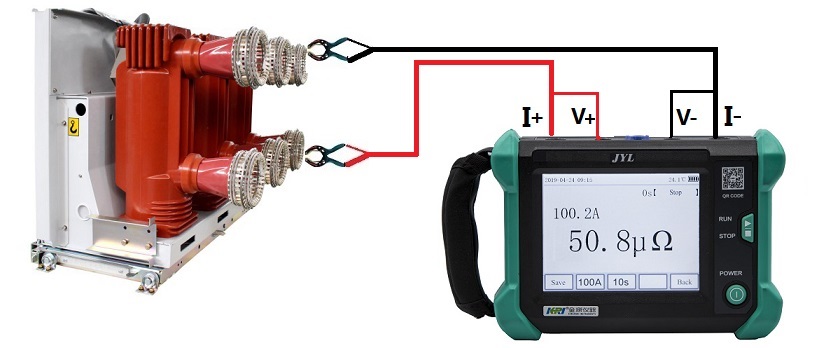

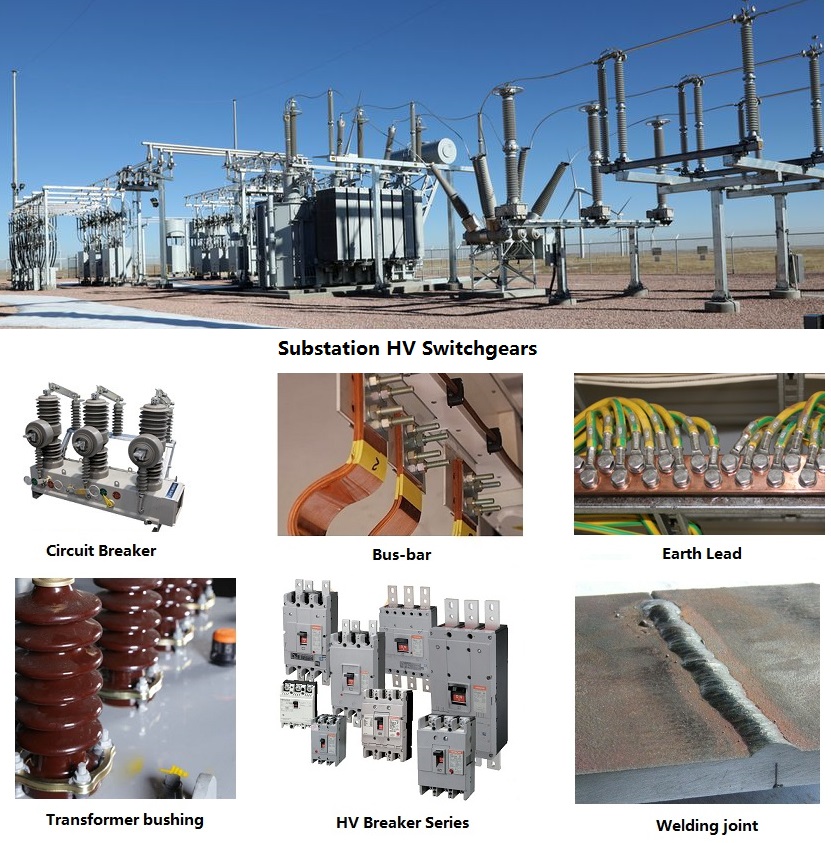

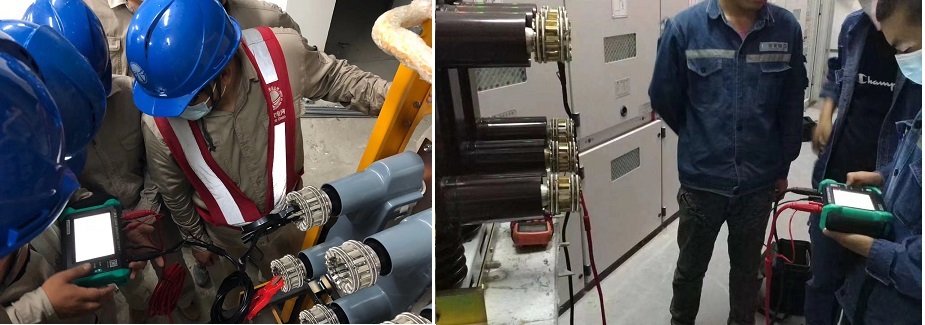

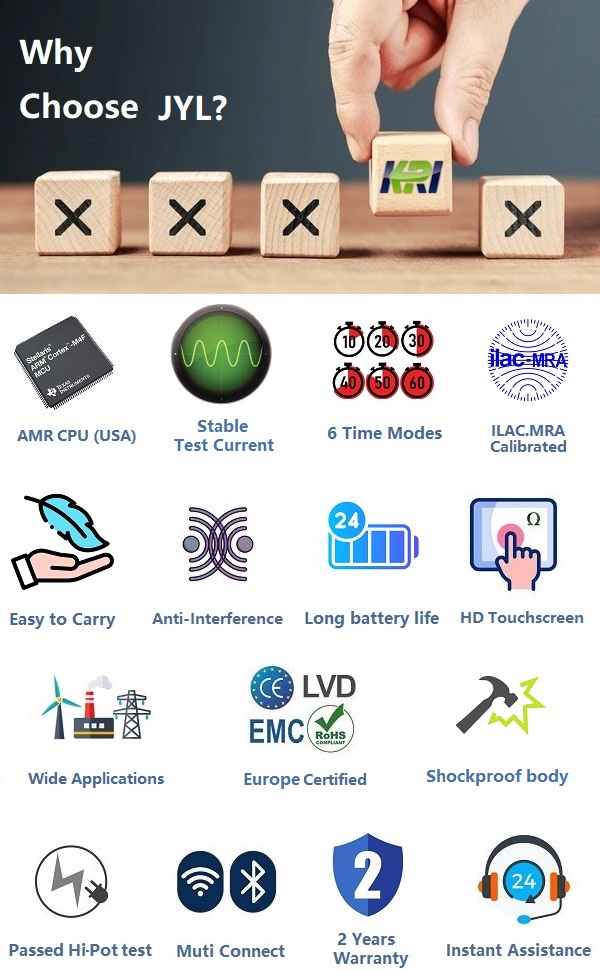

JYL incorporates the ARM (Advanced RISC Machines; USA) high-precision multi-core chip, itis a new generation of contact resistance tester basedon IEEE C57.09-1999(5.15)contact resistance test standardand got ILAC.MAR calibration certification, adoptsKelvin four-wire measurement method, which effectively eliminates the influence of the resistance of the test line on the test results.Thetester is just 1.9kgs with built-in rechargeable battery, so it is suitable for site testing work.JYL can satisfy the testingof contact resistance such ashigh-voltage switchgear, disconnect switch,SF6 & Vacuum circuit breaker, medium voltage CT, transformer bushing joints, GIS cabinet, bus-bar joints, earth leading contact, cable termination connection, welding joints, relay metal contact resistanceand so on.

High Voltage Circuit Breaker Contact Resistance Testing:

JYL Contact Resistance Tester Functions:

1.The output current is up to 100A which is suitable for most of the contact resistance items in substation, electric & power industry.

2.Test contact resistancerang:0.1µΩ ~ 5mΩ

3.The continuous test time under 100A current is more than 60s (with total 6 kinds of test time mode to choose from).

4. Strong anti-power frequency interference that can make sure the test precision in high frequency circumstances.

5. JYL has built-in lithium battery(12V/5.2AH),can perform 500 times tests by single charge.

6. Built-in blue tooth communication function(optional).

7. Equipped with highlight 5.6 inch color touch screen, so the tester can be used both indoor and outdoor.

8. With the function of monitoring and protecting the battery power and the temperature of tester.

9. Flash disk interface for exporting data. With data storage function, it can store 100 sets of testing data.

10. With function of automatic shutdown (shutdown without operation exceeding 5 minutes).

11. Tester shell has the function of insulation, anti creep, anti-wind, and anti-sand which is suitable for outdoor testing work.

JYL Contact Resistance Tester Operation Video:

JYL Contact Resistance Tester Technical specification:

|

Type |

JYL Handheld contact resistance tester |

|

|

Output Current |

50A |

100A |

|

Measurement Range |

0~10mΩ |

0~5mΩ |

|

Accuracy |

±(reading*0.5% ± 1μΩ) |

|

|

Current Accuracy |

±5% |

|

|

Minimum Resolution |

0.1μΩ |

|

|

Output Voltage |

about 2.0V |

|

|

Testing Duration |

Quick/10s /20s /30s /40s /50s /60s (Selectable) |

|

|

Battery Endurance |

>500 tests per full charge

(in 100 A “Quick” mode with 10 mΩ load)

|

|

|

Test Cable Resistance |

≤15mΩ |

|

|

Operation Temperature |

-20℃ ~40℃ |

|

|

Relative Humidity |

≤80%, No dew |

|

|

Dimensions / Weight |

L210mm x W150mm x H70mm / 1.9kg |

|

JYL Contact Resistance Testing Connection (Vacuum Circuit Breaker):

JYL's Main Applications

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun