Hazards of Partial Discharge(PD)

Hazards of Partial Discharge(PD)

According to the definition of the International Electrotechnical Commission IEC 60270, partial discharge (PD) is a localized electrical discharge that only partially bridges the insulation between conductors and which may or may not occur adjacent to a conductor.

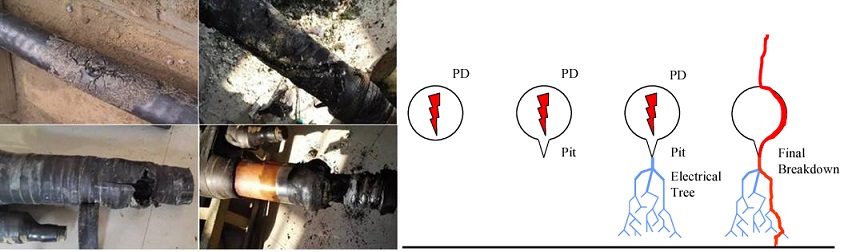

The harm of partial discharge to insulation includes the following aspects:

1. Charged particles (electrons, ions, etc.) impacting on insulation and destroying its molecular structure, which results in insulation damage;

2. Because of the impact of charged ions, the partial temperature of insulation rises, which easily leads to insulation overheating and carbonization in serious cases;

3. The continuous development of partial discharge will lead to insulation deterioration. The damage gradually enlarges, and ultimately shortens the normal life of insulation, reduces the short-term insulation strength, and may even cause the whole insulation to break down.

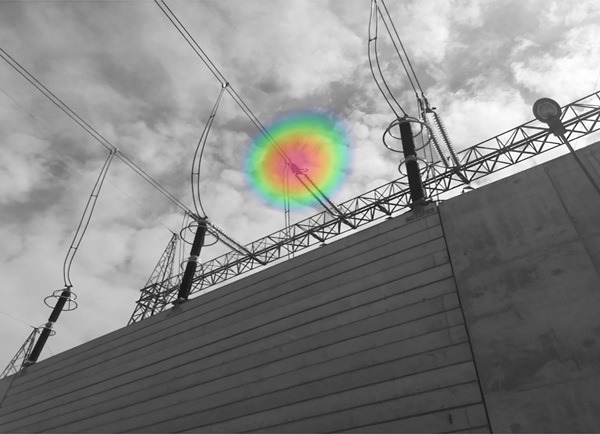

The fault detection of high-voltage transmission lines and distribution systems is a big challenge for insulation maintenance personnel. The main problem is the corona phenomenon. When the electric field strength ionizes the air molecules around the insulator, a chemical reaction will occur, which will corrode metal parts and weaken the ability of the insulating compound. The high energy produced by the corona discharge will cause serious damage to the line accessories, and serious fire and explosionphenomena can occur.

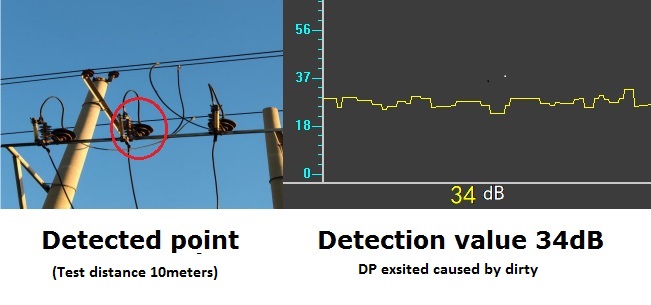

The application of traditional infrared imaging technology can find hot spots that cannot be detected by the naked eye. However, corona, arc, electric tracking and other phenomena are not necessarily accompanied by obvious heating, and the high temperature of the environment will also cover these phenomena, and control the equipment in the cabinet. It cannot be found with an infrared camera. However, these phenomena will produce obvious ultrasonic noise, which can be detected by the ultrasonic partial discharge detector. The ultrasonic inspection system completes the insulation inspection work, allowing humans to detect the sound of insulators, wire sleeves, transformers, end sleeves, lightning rods and other faults.

The significant dangers of partial discharge (PD) are well known; however, high-altitude, long-distance, and non-visible inspections of PD are often less effective. Therefore, utilizing ultrasound for partial discharge testing is an effective method. With a detection range of up to 30 meters, it can cover the majority of electrical equipment, enabling rapid and accurate identification of partial discharge fault points while ensuring the safety of testing personnel. This method overcomes the significant limitation of infrared testing, which can only be conducted under visible conditions, and is also cost-effective, making it ideal for budget-conscious electrical maintenance and repair companies.

GTPD-3 partial discharge detector is a detection device which can diagnose hidden trouble of power line by collecting and analyzing the abnormal ultrasonic signal of power line. It is also suitable for partial discharge detection of insulator, cable terminal, high voltage bushing, CT\ PT, lightning arrester, switch, etc. This device realizes the location and type of fault hidden danger with the power line and equipment in live state.

1. Portable design, small size, light weight, easy to carry. It can be working on vehicles with a speed of 30km/h.

2. It is easy to locate, focus and take photos on the fault of the equipment through camera and laser detector,

3. The screen of GTPD-3 partial discharge detector is a color touch type, which can display waveforms, dB values, temperature, humidity and GPS information.

4. The detected abnormal ultrasonic signal can be converted into audible sound signal and waveform output.

5. Embedded GPS receiver automatically stores coordinate data and provides GPS navigation function to facilitate inquiry and preservation of detection paths.

6. GTPD-3 partial discharge detector has the function of detecting temperature and humidity, and can detect temperature and humidity in real time.

7. With data storage function, data playback can be realized.

8. High sensitivity, directivity , it can locate the fault accurately.

9. GTPD-3 partial discharge detector is suitable for noise environment and is not affected by environmental noise.

10.Early detection of faults can be detected prior to other detection methods such as infrared detection.

11. By the non-contact live detection method, detection distance of partial discharge detector can reach to more than 30 meters, safe and reliable, without affecting the normal operation of equipment.

|

Operation System |

WINCE6.0, CPU 533MHz |

Camera |

300 thousand pixel HD camera |

|

Memory |

256MB DDR2, 1GB Nand Flash |

Accessories |

GPS, Temperature and humidity sensors, High brightness laser pointer |

|

Display |

4.3 Inches true color touch LCD, resolution: 480×272 |

Storage function |

GPS coordinate data, time/Date, Temperature/humidity |

|

Interface |

SD CARD, USB, Series port, earphone |

Central Frequency |

40kHz |

|

Ambient Temperature |

-25℃~70℃ |

Relative humidity |

0~95% |

Infrared Thermography (IRT) and Partial Discharge (PD) testing are two widely adopted condition monitoring techniques in modern power systems, each with distinct applications and technical strengths. IRT detects surface temperature anomalies to identify potential faults caused by increased electrical resistance, such as loose connections, overloads, or deteriorated contacts. Based on passive thermal radiation measurement, IRT is simple to operate, allows for non-intrusive and live inspections, and is particularly effective for components like switchgear, busbars, and cable terminations. However, it has notable limitations: it can only detect faults that produce significant heat and cannot identify early-stage insulation degradation or internal defects. The results are also influenced by ambient temperature, surface emissivity settings, and operator experience. In contrast, PD testing detects small electrical discharges occurring within or on the surface of insulation systems. These discharges often indicate the onset of insulation breakdown, such as voids, cracks, surface contamination, or moisture ingress, allowing for much earlier detection of critical insulation failures.

In summary, IRT is well-suited for identifying resistive faults and surface heating, while PD testing is more effective at detecting internal insulation degradation at an early stage. Integrating both methods enables a comprehensive asset monitoring strategy, combining surface thermal detection with internal dielectric diagnostics. Industry standards recommend joint application, and the reliability of the results depends heavily on the competency of the operators. Certified training (e.g., FLIR Level I/II for thermography or PD specialist training from EA Technology) is strongly recommended. By selecting the appropriate method based on asset type, voltage level, and environmental conditions, utilities and asset managers can significantly improve system reliability and reduce the risk of unplanned outages and catastrophic failures.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun

turn ratio tester, transformer test instrument, winding resistane