Understanding the factors that influence the resistivity of materials is crucial in applications like transformers and motor windings, where precise resistance control is essential for efficiency and performance. This article delves into how temperature, material composition, and environmental conditions such as humidity affect resistivity. For transformers and motor windings, the resistivity of the winding material significantly impacts the device's performance and efficiency. Factors such as the type of metal used (commonly copper or aluminum), temperature fluctuations, and moisture levels are critical in determining the overall resistivity and, consequently, the electrical performance of these devices.

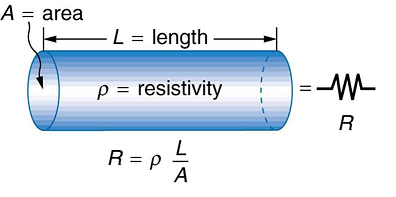

Resistivity is a physical quantity used to represent the resistance characteristics of various substances. The resistance of a conductor with a length of 1m and a cross-sectional area of 1m2 made of a certain material is numerically equal to the resistivity of this material. At a certain temperature, the resistance of the material is:

ρ=RA/L

where ρ is the resistivity, L is the length of the material, and A is the cross-sectional area of the material. It can be seen that the resistance of the material is proportional to the length of the material, that is, when the material and cross-sectional area are constant, the longer the length, the greater the resistance of the material; and it is inversely proportional to the cross-sectional area of the material, that is, when the material and the length are not the same. When changing, the larger the cross-sectional area, the smaller the resistance

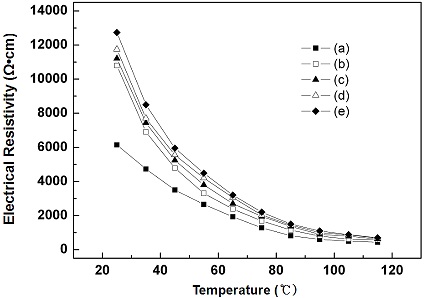

The resistance of general materials decreases with increasing temperature and humidity. In contrast, surface resistance (rate) is sensitive to ambient humidity, while bulk resistance (rate) is more sensitive to temperature. As humidity increases, surface leakage increases, and the body's conduction current increases. When the temperature increases, the moving speed of the carriers increases, and the absorption current and conduction current of the medium will increase accordingly. It is reported that the resistance of the general medium at 70C is only 10% of that at 20C. Therefore, to measure the resistance of a material, it is necessary to specify that the sample is in equilibrium with the ambient temperature and humidity.

When measuring winding resistance, it is essential to use instruments with temperature conversion functions. These instruments can convert resistance values to standard temperatures (20°C, 75°C, 120°C), ensuring more accurate readings.

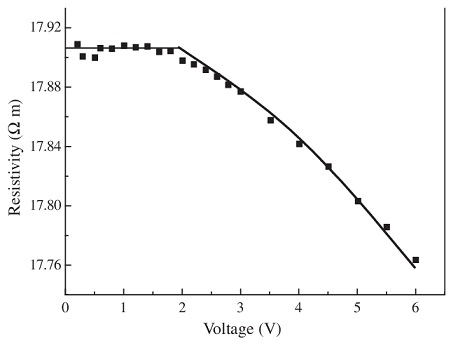

Dielectric resistance (rate) values generally do not remain constant over a wide voltage range, which does not apply Ohm's law. At room temperature, in the lower voltage range, the on-current increases linearly with the applied voltage, and the resistance value remains unchanged. After a certain voltage is exceeded, the movement of ions increases, the on-current increases faster than the test voltage, and the resistance of the material decreases rapidly. Therefore, the higher the test voltage applied, the lower the resistance of the material, resulting in possible large differences in the resistance test of materials with different voltages.

The insulating material adopts DC high voltage, and the current passing through the sample is very small, which is easily affected by external interference, resulting in a large test error. Thermoelectric potential and contact potential are generally small and can be ignored; the electrolytic potential is mainly wet samples generated by different metal contacts, only about 20mV, and static testing does require relatively low humidity. When testing in a dry environment, Electrolytic potential can be eliminated. Therefore, the external interference is mainly the coupling of stray current or potential generated by electrostatic induction.

Commonly used metal conductor resistivity ρ(Ω·m):

(1) Silver 1.65 × 10-8

(2) Copper 1.75 × 10-8

(3) Gold 2.40×10-8

(4) Aluminum 2.83 × 10-8

(5) Tungsten 5.48 × 10-8

(6) Iron 9.78 × 10-8

(7) Platinum 2.22 × 10-7

(8) Manganese Bronze 4.4 × 10-7

(9) Mercury 9.6 × 10-7

(10) Constantan 5.0 × 10-7

(11) Nickel-chromium alloy 1.0 × 10-6

(12) Iron-chromium-aluminum alloy 1.4 × 10-6

(13) Al-Ni-Fe alloy 1.6 × 10-6

It can be seen that the resistivity of pure metals in conductors is small, and the resistivity of alloys is large. The resistivity of silver is the smallest, but the price of silver is expensive. Usually, silver is rarely used as a wire, and it is only used for special needs. The wire is generally made of copper or aluminum with a lower resistivity. Aluminum is cheaper than copper, so aluminum A lot of wires are used. The resistance wires of electric furnaces and resistors are generally made of alloys with higher resistivity.

The resistivity of various materials changes with temperature, and the resistivity of metals increases with temperature, so the resistance of metal conductors also increases with temperature. This property of resistance can be used to make resistance thermometers ; If the change of conductor resistance with temperature is known, then the resistance of the conductor can be measured, and the temperature of the conductor can be known in turn.

Therefore, when measuring winding resistance, you should try your best to choose an instrument with a material conversion function. For example, the instrument can select the copper/aluminum test item and cooperate with the temperature selection, so that the measured resistance value is more accurate.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun