The transformer winding temperature rise test simulates actual operating conditions to measure the temperature increase of the transformer windings under rated load. The core objective is to verify that the winding temperature rise is controlled within the design and standard limits (such as IEC, GB standards), ensuring the long-term safety and reliability of the transformer. Excessive temperature rise accelerates the aging of insulation materials, leading to a decline in insulation performance and potentially causing severe faults such as short circuits or breakdowns, while also affecting transformer efficiency and service life.

This test assesses the thermal stability of the windings, providing a basis for design optimization and ensuring that the heat dissipation structure is reasonable to prevent local overheating. It is also a necessary part of factory testing, directly reflecting the quality of the manufacturing process and preventing abnormal temperature rises due to material defects or assembly issues. Furthermore, temperature rise data can serve as an important parameter for evaluating the transformer's load capacity, guiding users to reasonably plan the operating load and improving grid stability. As a key item in type testing, the winding temperature rise test serves as a "temperature red line" for ensuring safe equipment operation and is also an important indicator for measuring transformer energy efficiency and environmental performance.

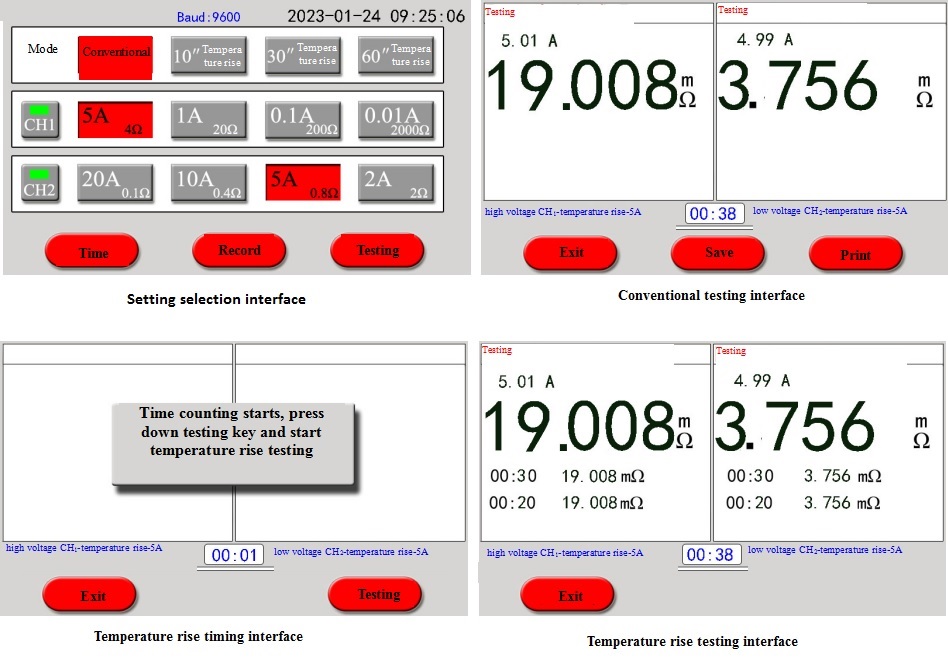

JYR-20W Main Operation Interface for Heat Run Testing

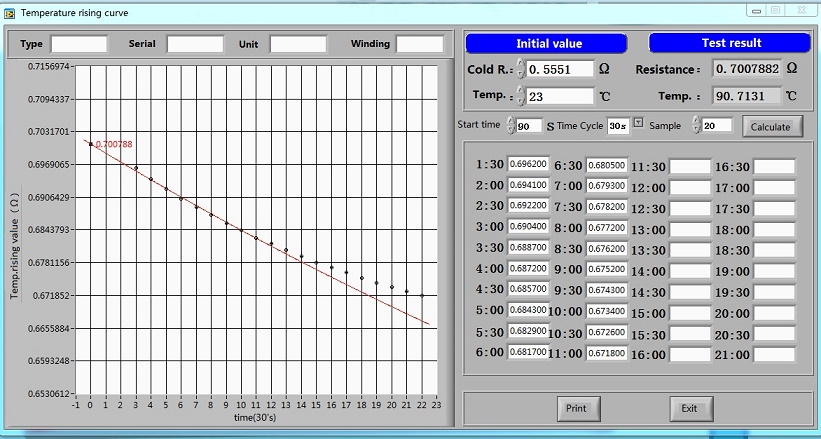

JYR-20W Heat Run Curve:

TECHNOLOGY SPECIFICATION:

|

TYPE |

JYR 20W |

|

|

Output current |

HV: 5A, 1A, 0.1A, 0.01A |

LV: 20A, 10A, 5A, 2A |

|

Testing range |

0~2 kΩ |

0~2Ω |

|

Accuracy |

0.2%±1μΩ |

0.2%±0.2μΩ |

|

Output voltage |

DC 20V |

DC4V |

|

Minimum resolution |

0.1μΩ |

0.1μΩ |

|

Power supply in operation |

AC220V±10%, 50Hz±1Hz |

|

|

Temperature in operation |

-20~40℃ |

|

|

Relative humidity |

≤80%RH, No forming dew |

|

|

Volume |

Length 410 mm Width 440 mm Height 210 mm |

|

|

Net weight |

15.7 kg |

|

|

Temperature rising timing rate |

10”,30”,60” are optional |

|

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun