Why is cooling so important?

1.Heat dissipation extends transformer life, improves reliability, and allows overload operation.

2. The choice of cooling system depends on the transformer's power, type, and operating environment.

How are transformer cooling systems classified?

Small transformers are cooled by natural air flowing through the transformer's interior and exterior. As power increases, cooling systems become more complex, using water, gas, synthetic fluids, and mineral oil (most commonly) as cooling media.

The Spanish standard UNE-EN 60076 specifies the following key considerations for the design, manufacture, and testing of insulation, distribution, and power transformers:

• Materials: This standard specifies the permissible materials for cooling system components (such as radiators, pumps, fans, etc.).

• Dimensions: This standard defines the calculation and sizing criteria for cooling system components.

• Testing: This standard specifies the tests required to verify proper operation.

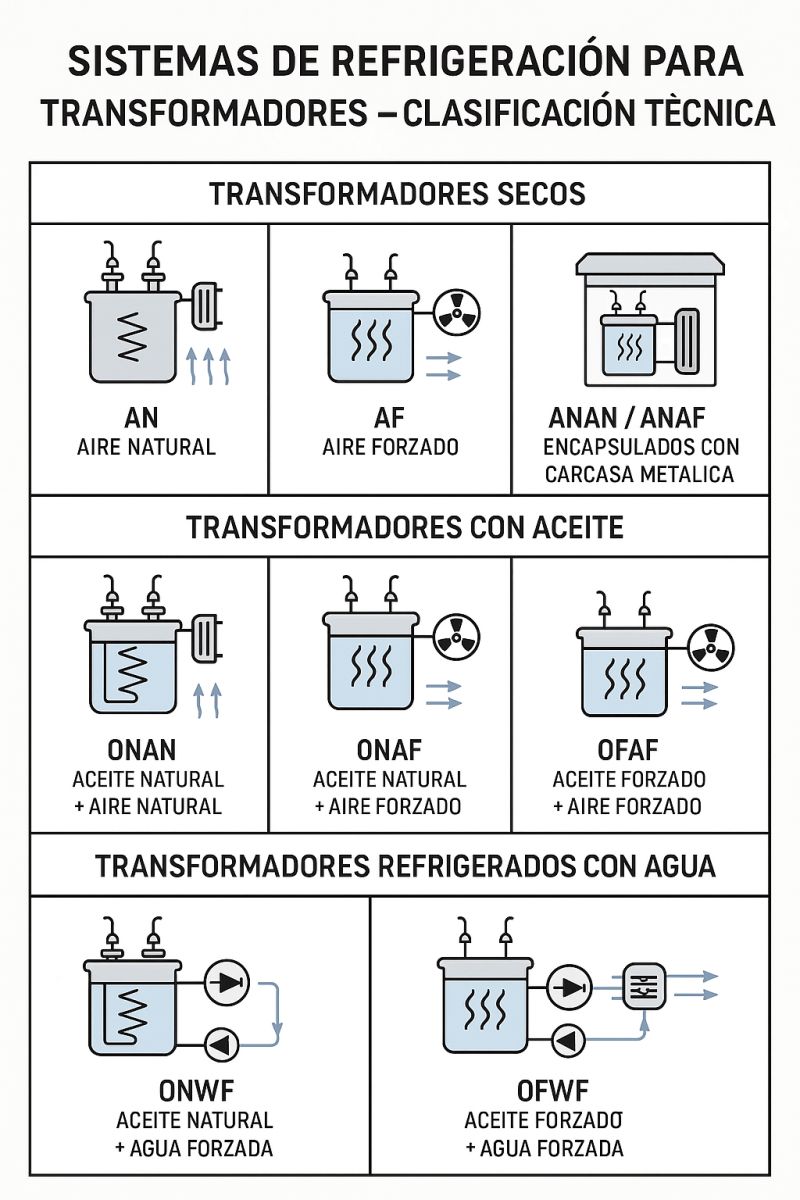

In summary, the standard sets out the technical and operational specifications for various requirements to ensure the safety and reliability of transformers in different application scenarios and power levels. Cooling systems are divided into nine categories, coded with four letters, as follows:

Dry-Type Transformer Systems

▪ #AN (Natural Air): Natural air circulation, suitable for 1.5 MVA and below, with no moving parts.

▪ #AF (Forced Air): Fan-driven ventilation, suitable for 15 MVA and below, activated by a thermal sensor.

▪ #ANAN / ANAF: Encapsulated type with a metal casing.

Oil-Immersed Transformer Systems

▪ #ONAN (Natural Oil Circulation - Natural Air Cooling): Natural convection of the oil with passive heat dissipation via a radiator, suitable for 30 MVA and below.

▪ #ONAF (Natural Oil Circulation - Forced Air Cooling): Same principle as ONAN, but equipped with a fan that activates when overheating occurs.

Large-Capacity Active Systems

▪ #OFAF (Forced Oil Circulation - Forced Air Cooling): Equipped with an oil pump and a high-power fan, requiring an oil-to-air heat exchanger, suitable for high-intensity, continuous operation. ▪ #ONWF / #OFWF (Water Cooling): Forced water flow heat exchanger with high thermal efficiency, suitable for power plants and enclosed environments.

Technical Diagram

Transformer Cooling System

Technical Classification by Category:

#Dry-Type Transformer

▪ AN → Natural Air

▪ AF → Forced Air

▪ ANAN/ANAF → Encapsulated with Metal Housing

#Oil-Flow Transformer

▪ ONAN → Natural Oil + Natural Air

▪ ONAF → Natural Oil + Forced Air

▪ OFAF → Forced Oil + Forced Air

#Water-Cooled Transformer

▪ ONWF → Natural Oil + Forced Water

▪ OFWF → Forced Oil + Forced Water

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun