When it comes to high-value electrical assets like transformers, early fault detection can mean the difference between a simple repair and a catastrophic failure.

That’s where the DGA Test comes in — a powerful diagnostic tool that helps identify the internal faults in a transformer before they escalate.

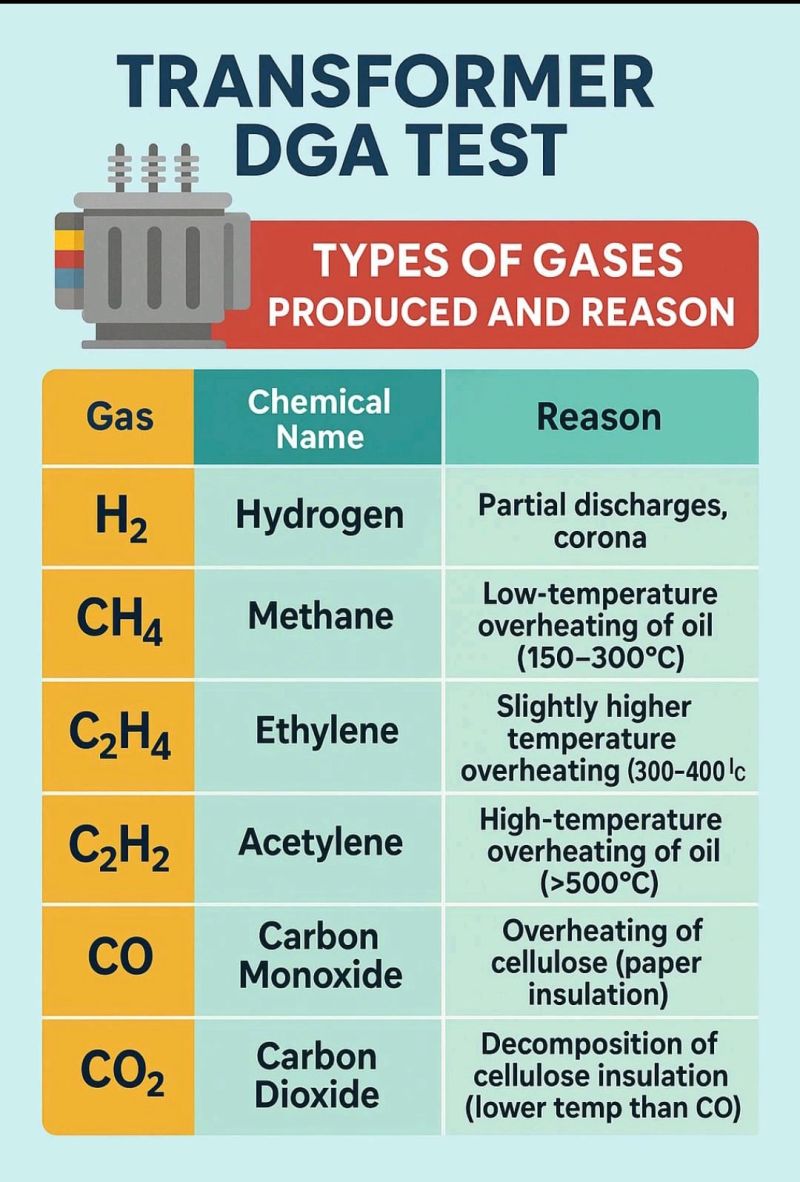

Here’s a detailed breakdown of the gases commonly detected during DGA and what they reveal about transformer health:

Types of Gases and Their Diagnostic Significance:

Gas Chemical Name Indication / Root Cause

H₂ – Hydrogen Partial discharges or corona activity. A key marker of incipient electrical discharges.

CH₄ – Methane Formed during low-temperature oil overheating (150–300°C). Often indicates hot spots or thermal faults in windings.

C₂H₄ – Ethylene Sign of moderate overheating (300–400°C). Suggests worsening thermal stress compared to CH₄.

C₂H₂ – Acetylene The most alarming gas! Associated with high-temperature arcing faults (>500°C), indicating potential internal arcing or severe insulation failure.

CO – Carbon Monoxide Comes from overheating of cellulose (paper) insulation. If detected, insulation aging or localized heating is a concern.

CO₂ – Carbon Dioxide Indicates slow thermal degradation of paper insulation at lower temperatures than CO. A good long-term aging indicator.

Why This Matters for Asset Managers and Engineers:

Preventive Maintenance: Detect issues early and avoid forced outages.

Root Cause Analysis: Different gases = different fault types.

Life Extension: Monitor insulation aging and optimize loading.

Safety & Reliability: Stay ahead of catastrophic failures.

Pro Tip: It’s not just about individual gases. The ratios between gases, their rate of increase, and absolute concentrations help pinpoint whether the issue is electrical, thermal, or incipient.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun