Insulation Resistance Value

The insulation resistance should not be lower than 70% of the factory test value.

Temperature Conversion

If the test temperature differs from the factory test temperature, convert the insulation resistance to the same temperature for accurate comparison.

Absorption Ratio Measurement

For transformers rated at 35kV and above with capacities of 4000kVA or more, the absorption ratio should be measured. The value should show no significant difference from the factory value and should be at least 1.3 at room temperature. When R60s (60-second insulation resistance) exceeds 3000MΩ, the absorption ratio requirement can be waived.

Polarization Index Measurement

For transformers rated at 220kV and above with a capacity of 120MVA or more, it is recommended to use a 5000V megohmmeter to measure the polarization index. The measured value should show no significant difference from the factory value and should be at least 1.3 at room temperature. When R60s exceeds 10000MΩ, the polarization index requirement can be waived.

Insulation Resistance

Convert the insulation resistance to the same temperature as the last test and ensure there are no significant changes; generally, the value should not be less than 70% of the previous test result.

Absorption Ratio and Polarization Index

For transformers rated at 35kV and above, the absorption ratio should be measured and should not be lower than 1.3 at room temperature. If the absorption ratio is low, measure the polarization index, which should be at least 1.5. If the insulation resistance is greater than 10000MΩ, an absorption ratio of at least 1.1 or a polarization index of 1.3 is required.

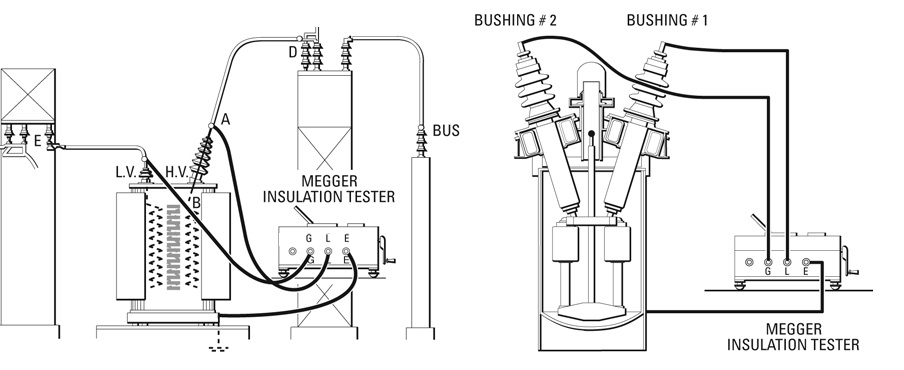

Selection of megohmmeter

For transformers rated at 220kV and above, use a 2500V or 5000V megohmmeter with a minimum output current capacity of 3mA.

Discharge

Ensure the test windings are fully discharged before measurement.

Temperature Standard

Use the top-layer oil temperature as a reference; keep temperatures consistent across measurements and aim to test when the oil temperature is below 50°C. Insulation resistance values should be converted based on temperature, although absorption ratios and polarization indices do not require temperature conversion.

Measurement Locations

For transformers with sealed cable or GIS connections, measure the cable and GIS side windings at the neutral point. For other independent windings, short-circuit and ground them.

Testing Under Special Conditions

If oil dielectric loss or moisture content in the oil is high, or if oil leakage suggests potential moisture ingress, perform insulation testing on the core and clamping components.

Special Cases for Commissioning and Aged Transformers

JYM insulation resistance tester

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun