What is Transformer No-load and Load Testing and How to Test Them?

Why is it necessary to perform no-load and load tests on a transformer?

The no-load and load tests of a transformer are conducted to assess its performance and operational condition, ensuring that the transformer can operate safely, stably, and efficiently under actual working conditions. These two tests focus on different operational states of the transformer, aiming to understand its core parameters and performance under various load conditions.

1. No-load Test

The no-load test, also called "no-load loss" or "excitation current test," is conducted by applying rated voltage to the primary winding while the secondary winding is open. The main purpose is to evaluate the core performance, no-load losses, and excitation current of the transformer. Specific reasons include:

Core Loss (No-load Loss) Measurement: Under no-load conditions, the losses in a transformer are primarily caused by hysteresis and eddy currents in the core. Measuring these losses helps assess the quality of the core material and the manufacturing process.

Excitation Current Measurement: By measuring the excitation current flowing into the primary side during no-load operation, one can understand the current required to maintain the magnetic flux in the transformer. This helps in analyzing the magnetic properties of the core.

Core Performance Evaluation: The no-load test also helps detect the saturation state of the core and its magnetization characteristics under different voltage levels, ensuring that the core operates within the designed range.

2. On-load Test

The on-load test is conducted by connecting a load to the secondary side of the transformer to assess its performance under actual working conditions. On-load testing can be further divided into short-circuit testing and load loss testing. The main reasons include:

Copper Loss (Load Loss) Measurement: The losses in a transformer under on-load conditions are mainly caused by the current in the windings, which results in copper losses. The on-load test can accurately measure the load losses of the transformer, allowing the assessment of its energy efficiency.

Transformer Efficiency Evaluation: The on-load test allows the calculation of the transformer’s efficiency under different load conditions, helping to understand energy losses and performance under various loads.

Voltage Regulation Characteristic Analysis: The on- load test also evaluates the voltage regulation characteristics of the transformer, i.e., the change in secondary voltage when going from no-load to full-load. This is critical for maintaining voltage stability in the power grid.

Short-circuit Impedance and Voltage Drop: The load test measures the short-circuit impedance and voltage drop of the transformer, which helps assess its response under fault conditions.

The no-load test of the transformer is to apply the rated voltage from the coil on one side of the transformer, and the other coils are open. Measure the no-load loss and no-load current of the transformer. The no-load current is expressed as a percentage of the rated current.

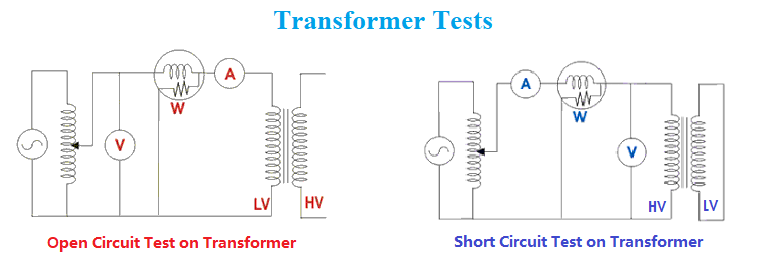

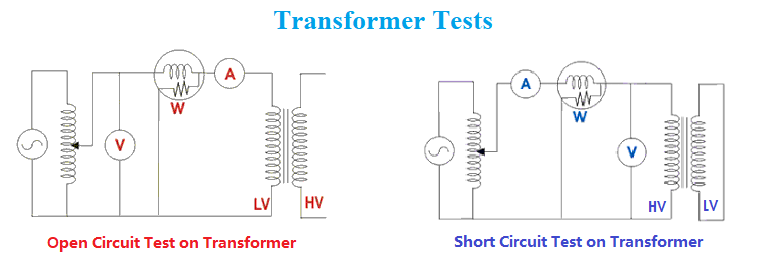

1. The no-load test is to measure the no-load loss and no-load current under the rated voltage. During the test, the high-voltage side is open circuit, the low-voltage side is pressurized, the test voltage is the rated voltage of the low-voltage side, the test voltage is low, and the test current is a percentage of the rated current. a few thousandths or a few thousandths.

2. Selection of power supply capacity for transformer no-load test: ensure that the power supply waveform distortion does not exceed 5%, and the no-load capacity of the transformer should be less than 50 of the power supply capacity; the no-load capacity should be less than the capacity of the voltage regulator if the voltage regulator is used for pressure. When using the generator set test, the no-load capacity should be less than 25% of the generator capacity.

The test voltage of the no-load test is the rated voltage of the low-voltage side, and the no-load test of the transformer mainly measures the no-load loss. No-load losses are mainly iron losses. The magnitude of the iron loss can be considered to be independent of the size of the load, that is, the iron loss under a dry load such as the loss at no load, but this is the case at the rated voltage. If the voltage deviates from the rated value, since the magnetic induction in the transformer core is in the saturation section of the magnetization curve, the no-load loss and no-load current will change sharply. Therefore, the no-load test should be carried out at the rated voltage.

Note: When measuring the no-load or load loss of a large transformer, because the power factor is very low, the cosp can be less than or equal to 0.1, so a wattmeter with low power factor must be used.

3. Through the no-load test, the following defects of the transformer can be found:

a. Poor insulation between silicon steel sheets.

b. Partial short-circuit burning between the poles of the iron core and between the chips.

c. Insulation parts such as core bolts or binding steel belts, pressure plates, and upper yokes are damaged and short-circuited.

d. The silicon steel sheet in the magnetic circuit is loose, dislocated, and the gap is too large.

e. The iron core is grounded at multiple points, the coil has inter-turn, inter-layer short-circuit or parallel branch turns, and the magnetic potential is unbalanced, etc.

f. Misuse of high-consumption inferior silicon steel sheet or wrong design calculation.

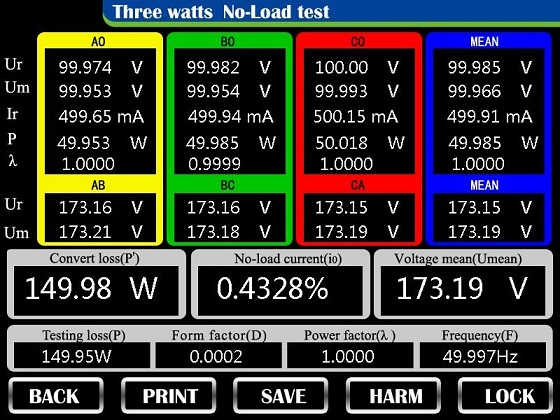

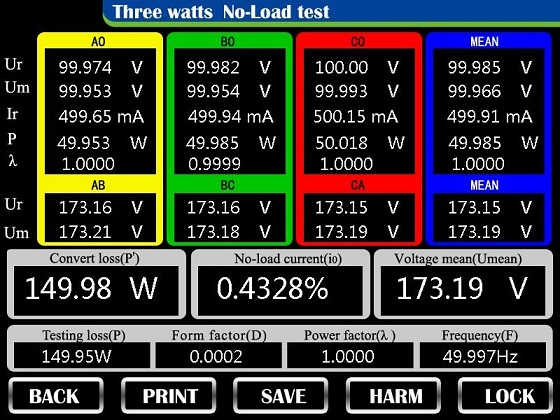

The results of the phase separation measurement are judged according to the following principles:

1) Since the magnetic circuits of the ab phase and the bc phase are completely symmetrical, the measured losses P0ab and P0bc of the ab phase and the bc phase should be equal, and the deviation should generally not exceed 3%.

2) Since the magnetic circuit of the ac phase is longer than the magnetic circuit of the ab phase or the bc phase, the loss measured by the ac phase should be larger than that of the ab phase or the bc phase (35kV and below transformers are generally 30% to 40%, 110kV). and above transformers are generally 40% to 50%).

Example 1: A 90MVA, 220/121/38.5 transformer, I0=0.23%.

Single phase: pab=41.3kW=pa+pbpa=28kW pc=2.35pa=4.95pb

pac=93.8kW=pa+pcpb=13kW

pbc=79.1kW=pb+papc=65kW

The analysis found that the first turn (outlet end) of the C-phase low-voltage winding had an inter-strand short circuit, the low-voltage winding was 10 2.3×10.5 flat copper wires in parallel, and there were two wires on the outer layer to form a short circuit, and some of the copper wires were melted. A major accident.

Illustrate:

1) Although the inter-turn short circuit has developed to the point where the copper wire has melted, I0 is far smaller than the design value, and the three-phase unbalance is not prominent. 2) The inter-turn short circuit includes inter-conductor, inter-turn, and inter-layer short circuits. Compared with the three, the initial circulating current between the wires is the smallest (assuming the same contact resistance at the short circuit). It shows that the no-load loss test is feasible to find the short-circuit point.

Example 2: The no-load data of a transformer is as follows:

Ab excitation, bc short circuit, p0ab=44.6kW

bc excitation, ac short circuit, p0bc=44.6kW

ac excitation, ab short circuit, p0ac=55.2kW

At that time, the single-phase no-load loss was converted to three-phase no-load loss, which was consistent with the factory data, and the data was considered normal. Light gas action occurs after being put into operation.

Analyze the relationship of no-load loss of each phase: p0ac/p0ab=p0ac/p0bc=1.26, this data is abnormal. Experience has proved that for such a large transformer, it should be normal if it is greater than 1.4. After eliminating the winding and tap changer problems, it is believed that the fault may be in the B-phase iron core, and the possibility of partial discharge cannot be ruled out.

The rated voltage phase no-load test results are as follows:

bc excitation, ac short circuit p0bc=37.6kW, power on for 20 minutes without gas, loss data unchanged;

ac excitation, ab short circuit p0ac=52.6kW, loss is stable, no gas, after 14 minutes, p0ac suddenly rises to 58.8kW, at the same time, gas is generated, and the gas reaches 600ml in 50 seconds;

Ab excitation, bc short circuit p0ab=37.2kW, after 2 minutes, p0ab suddenly rises to 42.6kW, and gas is generated at the same time. It can be seen from the above test that when the magnetic flux passes through phase A, the loss will increase and gas will be generated. In order to determine whether the fault is in phase A, repeat the no-load test of bc excitation and ac short circuit. When the rated voltage is reached, the continuous After 30 minutes, the loss p0ab remains unchanged and no gas is produced.

Analyze:

1) The fault is in the A-phase magnetic circuit (including the upper and lower iron yokes between AB);

2) The original fault was in phase B, and now it is in phase A, and it appears and disappears from time to time, which proves that the fault point is movable, and it is estimated that it is a metal conductor.

After inspection, the lower iron yoke pad was knocked off, and finally the fault point was found: there was a piece of silicon steel under the AB phase lower clip winding limb, which short-circuited the iron yoke by one third.

JYW6100 Transformer No-loads and On-loads Power Factor Tester

Kingrun Transformer Instrument Co.,Ltd.

Please Check More Transformer/Substation Testers from Kingrun: