When the Contact Resistance Tester testing on the spot, everyone will find many problems, the most common problem is that when the voltage wiring loop of the tester is in poor contact or open, the tester will also display a value, and the following will occur at this time:

The voltage loop is open and there is no strong electric field interference at the test site. This happens because the differential mode voltage at the amplifier input is essentially 0, so the instrument displays a test value close to 0. If the tester has sufficient field test experience, he can infer from the field situation that the instrument is an exception. The final accurate test results can be obtained by eliminating the instrument voltage loop test line.

Poor contact of voltage circuits. In most cases, if you operate for a long time, the terminal blocks of the circuit breaker will form an oxide film or oil film on the appearance of the junction box. It is possible to clamp the voltage test clamp of the loop resistance meter to such a terminal block. If it is a poor contact, then the voltage test clip itself will also have a positive contact resistance. First, the contact resistance value is compared to the internal resistance value of the voltage sampling loop, which can greatly affect the test results.

The voltage circuit is disconnected or poorly connected, and there is strong electromagnetic interference at the test site, such as the bus bar is charged. At this time, the charged bus passes through the capacitor with air as the medium, causing interference with the tester. For both voltage test lines, differential mode voltages appear across the voltage acquisition line of the loop tester due to interference.

Other Related Articles:

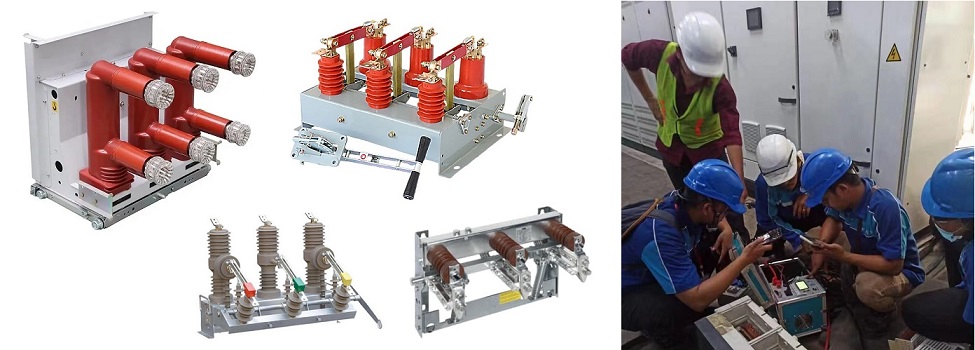

Why Does the Contact Resistance Testing Need 100A or Higher?

Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

How to measure the contact resistance without changing the circuit?

How to Correctly Test the Contact Resistance of HV Switchgear or Circuit Breaker?

Why Does Excessive Contact Resistance Occur In Electrical Secondary Circuits?

What is the Testing Checklist for 110kV/220kV Substation Acceptance and Maintenance Testing?

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun