1. Dust control

Among the factors that cause partial discharge, foreign matter and dust are very important factors. The test results show that metal particles with a diameter of ф1.5μm can produce a discharge much greater than 500pC under the action of an electric field. Whether metallic or non-metallic powder, a concentrated electric field is generated, which reduces the initial discharge voltage of the insulator and the breakdown voltage. For this reason, it is important to keep the environment and the body clean during the transformer manufacturing process, and dust must be strictly controlled. Strictly control the degree to which the product is affected by dust in the production process, and establish a sealed dust-proof workshop.

2. Centralized processing of insulating parts

It is very important that it contains metal dust because once the insulation sheet is attached to the metal dust, it is difficult to completely remove it. Therefore, it is necessary to centralize the treatment in the isolation workshop and set up an area that must be isolated from other dust-producing areas.

3. Strictly control the processing burr of silicon steel plate

Transformer core parts are formed by longitudinal and cross-cutting. These cut cuts have varying degrees of burrs. Burrs not only cause short circuits between chips, but also increase losses and increase the thickness of the core. What's more: when the iron core is inserted into the yoke or is subjected to vibration during operation, burrs can fall on the fuselage and discharge may occur. Even if the burrs fall to the bottom of the box, they can be arranged in an orderly manner under the influence of the electric field, causing a potential discharge to the ground. Therefore, the core burr should be as small as possible. The burr of the core part of the 110KV product should not be greater than 0.03mm.

4. Leads, cold-pressed terminals

The use of lead-pressed terminals is an effective measure to reduce the amount of partial discharge. When using phosphor copper welding, a large amount of spatter slag is formed, which is easy to diffuse to the body and insulator. In addition, the source boundary area must be separated by submerged asbestos wires so that water can enter the insulation. If the moisture is not completely removed after insulating the winding, the partial discharge of the transformer will increase.

5. Rounded component edge

The purpose of rounding the edges of the parts:

Improve the field power distribution and increase the discharge starting voltage. Therefore, metal structural parts such as clamps, pull plates, pads and bracket edges, pressure plates and outlet edges, the walls of the box riser and the magnetic shielding cover on the inside of the box wall in the iron core must be rounded.

Prevents friction from generating iron filings. For example, the contact part of the clip's hanging hole with the lanyard or hook should be round.

6. Product environment and body coating in the process of final assembly

After the hull is vacuum dried, the hull should be sorted before packaging. The larger the product, the more complex the structure and the longer the completion time. When the stem is compressed and fastened tightly, the stem is exposed to air, during which moisture absorption and dust dispersion occur. Therefore, the car body should be cleaned in dust-proof areas such as when finished (or exposed to air). time) more than 8 hours, must be dried again. After the completion of the hull, the stage of vacuuming and tank filling begins. Since stem insulation absorbs moisture during the stem trimming phase, it is necessary to dehumidify the stem. This is an important measure to ensure the dielectric strength of high-voltage products. The method used is to vacuum the product. Determine the vacuum time according to the body,

7. Vacuum lubrication

The purpose of vacuum oil injection is to inject transformer oil in a vacuum, eliminate dead spots in the insulation structure of the product by vacuuming the transformer, completely evacuate the air, and then completely absorb the transformer body. After oil injection, wait at least 72 hours before testing the transformer, because the degree of penetration of the insulation material is related to the thickness of the insulation material, the temperature of the insulation oil, and the immersion time. The higher the degree of penetration, the less likely it is to ejaculate, so make sure that you have passed enough absorption time.

8. Sealing of fuel tank and parts

The quality of the sealing structure is directly related to the leakage of the transformer. If there is a leakage point, moisture will inevitably enter the inside of the transformer, causing the transformer oil and other insulating parts to absorb moisture, which is one of the partial discharge factors. Therefore, it must meet reasonable sealing values.

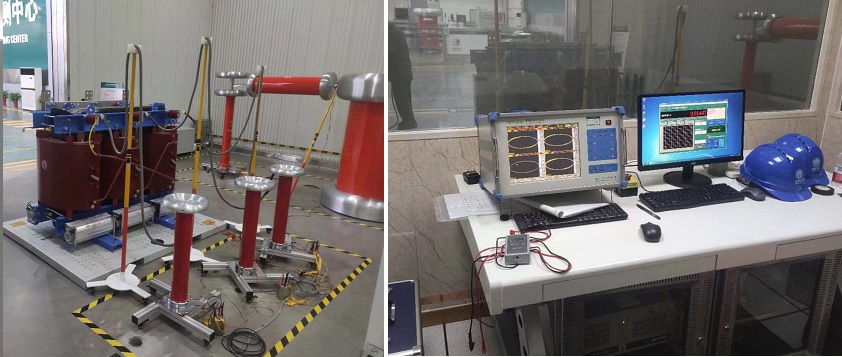

GTPD 92 partial discharge tester detector is a multi-functional handheld instrument. It is based on TEV, ultrasonic, UHF and HFCT detection methods to test the partial discharge of HV equipment.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun