Tan Delta testing is a crucial method for assessing the condition of a transformer's insulation system. Tan Delta, also known as the loss angle tangent, is the ratio of the active current component to the reactive current component in insulating materials, reflecting the dielectric loss of the insulation. Simply put, the smaller the tan δ value, the lower the dielectric loss of the insulating material, and the better its insulation performance. By measuring the tan δ value, the aging degree and moisture condition of the transformer's insulation materials can be evaluated, allowing for the early detection of potential insulation failures. Below, we will analyze the classifications of tan delta and its measurement principles in detail.

Dielectric loss: Under the action of an electric field, the energy loss inside the insulating material due to the hysteresis effect of dielectric conductance and dielectric polarization. Also called dielectric loss, referred to as dielectric loss. Under the action of the alternating electric field, the complementary angle δ of the included angle (power factor angle Φ) between the current phaser and the voltage phaser flowing in the dielectric is called the dielectric loss angle.Under the action of the alternating electric field, the charge accumulated in the dielectric has two components:

(1) Active power. One is the power consumed for heating, also known as the in-phase component;(2) Reactive power, also known as out-of-phase component. The ratio of the out-of-phase component to the in-phase component is called the dielectric loss tangent tanδ. tanδ=1/WCR (where W is the angular frequency of the alternating electric field; C is the dielectric capacitance; R is the loss resistance). The dielectric loss tangent is a dimensionless physical quantity.

Hysteresis loss

The hysteresis loss is due to the existence of a "hysteresis loop" in the iron core, so that the phase difference between the induced electromotive force and the magnetizing current is not equal to 90 degrees. We know that if it is 90 degrees, the current is "reactive". Now it is not equal to 90 degrees, which is equivalent to connecting an active current component in parallel.

By Steinmetz formula hysteresis loss, Wh =Kh f Bm1.6 w/m3Eddy current loss can be reduced by using an iron core made of thin laminated sheets and material with high electrical resistivity. It reduces the induced EMF and the amount of current flow.

2. Specific explanation:

When the transformer is working normally, the magnetic field generated by the secondary side current and the main part of the primary current are offset. The magnetic field left after cancellation should be roughly equal to the magnetic field at no load (when the secondary current is zero) (assuming resistance and leakage flux are ignored). Therefore, the "magnetizing current" I mentioned above should be equal to the no-load current of the transformer.When the transformer is no-load, if there is no loss, the input characteristics of the primary side should be equivalent to a pure inductance. With loss, the input current is equivalent to adding a resistor in parallel to the inductor. tanδ should be equal to the ratio of the current on this equivalent resistor to the current on the inductor.

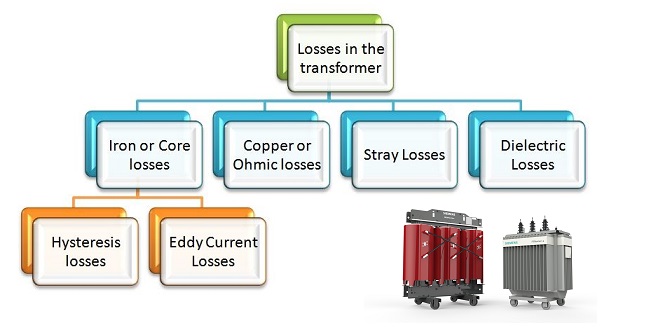

Other transformers loss types:

1. Iron Losses or Core Loss

Total Copper Loss, Pcu = I12R1 + I22R2 ;

The values of Resistance R1 of the primary winding and R2 of the secondary winding are constant.

It occurs in the insulating material and oil of the transformer. The transformer oils are subject to change its parameters such as dielectric strength, tan delta, moisture, chemical parameters (dissolved impurities – dissolution of copper), physical parameters, etc…

Additional points

1.Iron loss (Hysteresis loss, eddy current loss) and dielectric loss are no-load losses which are independent of the transformer load.

2.Whereas the copper loss and stray loss varies with the load current.

3.Iron loss is a constant loss and copper loss is a variable loss.

4.Copper loss is determined by the short circuit test and Iron loss is determined by the open circuit test.

Measuring tan Delta is of significant importance for transformers. Firstly, it helps identify the aging and deterioration of the internal insulation. Over time, the insulation materials in a transformer degrade due to electrical stress, thermal stress, and environmental influences, resulting in decreased dielectric performance and increased tan δ values. Regular measurement of the tan δ value allows for maintenance and repair before problems escalate into serious faults, preventing sudden power outages and equipment damage. Secondly, tan Delta measurement can detect moisture conditions in the transformer windings. Moisture in insulation materials significantly increases the tan δ value, potentially leading to insulation breakdowns and short-circuit faults. Through regular measurements, moisture issues can be identified and addressed early, ensuring the safe operation of the transformer. Additionally, tan Delta testing can be used for quality control and acceptance of new equipment, ensuring compliance with technical specifications and performance standards.

In summary, tan Delta measurement is a critical step in transformer maintenance. Regular monitoring of insulation status can effectively extend the transformer's service life, reduce the risk of failures, and enhance the reliability and safety of the power system.

Transformer Tan Delta Tester (JYC) control panel and test wiring diagram:

Measuring the dielectric loss (tan Delta) of a transformer typically requires specialized testing equipment. Here are the detailed steps:

Select Appropriate Testing Equipment:

Safety Checks:

Environmental Conditions:

Connect the Testing Equipment:

Calibrate the Equipment:

Apply Voltage:

Read Data:

Analyze Data:

Disconnect Equipment:

Record and Report:

By following these steps, you can effectively measure the dielectric loss of a transformer, evaluate its insulation condition, and ensure the safe operation of the transformer.

JYC automatic frequency conversion anti-interference dielectric loss tester is used for field anti-interference dielectric loss measurement or laboratory precision dielectric loss measurement,the instrument is an integrated structure, built-in dielectric loss bridge, variable frequency power supply, test transformer and standard capacitor, etc., adopts frequency conversion anti-interference and "Fourier" transform digital filtering technology, fully automatic intelligent measurement, the measurement data is very stable under strong interference, and the measurement results are from large to large, LCD screen display, built-in printer can print out.

JYC automatic frequency conversion anti-interference dielectric loss tester is used for field anti-interference dielectric loss measurement or laboratory precision dielectric loss measurement,the instrument is an integrated structure, built-in dielectric loss bridge, variable frequency power supply, test transformer and standard capacitor, etc., adopts frequency conversion anti-interference and "Fourier" transform digital filtering technology, fully automatic intelligent measurement, the measurement data is very stable under strong interference, and the measurement results are from large to large, LCD screen display, built-in printer can print out.

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun