Can a turns ratio tester Measure Transformers of Different Capacities?

Yes, a turns ratio tester can measure transformers of various capacities because the transformation ratio—defined as the ratio between the primary and secondary winding turns—is a structural design parameter that is not directly related to transformer capacity. Whether it is a small 50 kVA distribution transformer or a large multi-MVA power transformer, as long as the winding turns ratio is fixed, the tester can determine the transformation ratio by detecting the voltage (or current) signals of the primary and secondary windings.

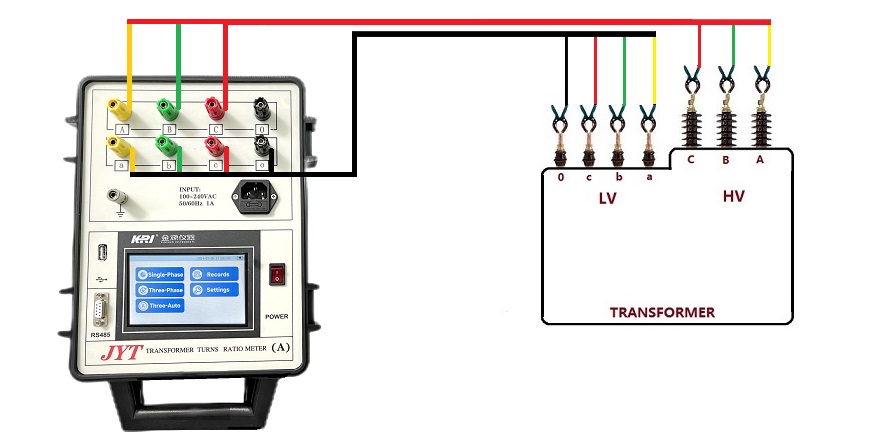

However, the tester’s voltage rating and testing mode must match the transformer under test. For example, when testing a 10 kV/0.4 kV distribution transformer, the tester should support a low-voltage side of 0.4 kV and a high-voltage side of 10 kV; for a 220 kV/110 kV power transformer, the tester must withstand the high-voltage insulation level (up to 220 kV) and have a high-voltage testing mode. As long as the voltage level is compatible and the test signal is effectively coupled to the windings, the ratio tester can be used for transformers of different capacities.

1. Small-capacity transformers (typically < 500 kVA, such as distribution transformers)

Fast and stable readings: With fewer winding turns (e.g., 10 kV/0.4 kV transformer, HV ≈ 2500 turns, LV ≈ 100 turns) and smaller excitation current (5–10 % of rated current), the magnetic circuit stabilizes quickly, and a complete test takes 10–30 seconds with minimal ratio fluctuation (≤ 0.1 %).

Turns error easily detected: Because of the small number of turns, even a single-turn error can cause a significant deviation. For instance, a 10 kV/0.4 kV transformer with a designed ratio of 25 will shift to 25.25 if the LV has one turn missing—beyond the ±0.5 % tolerance.

Abnormal phenomenon – sudden ratio jump at tap positions: Small transformers often use off-circuit tap changers (±5 %). Normally, ratios between taps vary proportionally (e.g., 25.5 → 25 → 24.5). If one tap shows a sudden deviation (e.g., 23), it may indicate oxidized or misaligned contacts, or a loose winding tap connection.

2. Large-capacity transformers (typically > 1000 kVA, such as power transformers)

Longer stabilization time: With more turns (HV > 10,000 turns) and a much larger magnetizing inductance (thousands of henries), the excitation process is slower. Without “automatic delay stabilization,” early readings may appear low (e.g., 19.8 → 20.0 after 10 s). Wait for stability before recording.

High-voltage insulation interference: At high voltage (e.g., 220 kV), surface contamination or damaged insulation on test leads can cause leakage or flashover, triggering insulation alarms or unstable ratio readings.

Abnormal phenomenon – ratio imbalance and abnormal excitation current:

If one phase shows a large ratio deviation (e.g., A 20.0, B 20.5, C 20.0; deviation 2.5 %) and a 30 % higher excitation current, it may indicate inter-turn short circuit.

If all ratios are normal but excitation current is abnormally low (≈ 2 % of rated), multi-point core grounding may exist, increasing core losses and reducing excitation efficiency.

1. Before testing

Select a suitable tester: use ≤ 500 V model for low-voltage small transformers; use 10 kV-class model for large transformers ≥ 110 kV.

Fully disconnect and discharge: use a grounding rod for ≥ 10 minutes for large transformers; short-circuit discharge for small ones.

Clean bushings and terminals, and use properly insulated test leads.

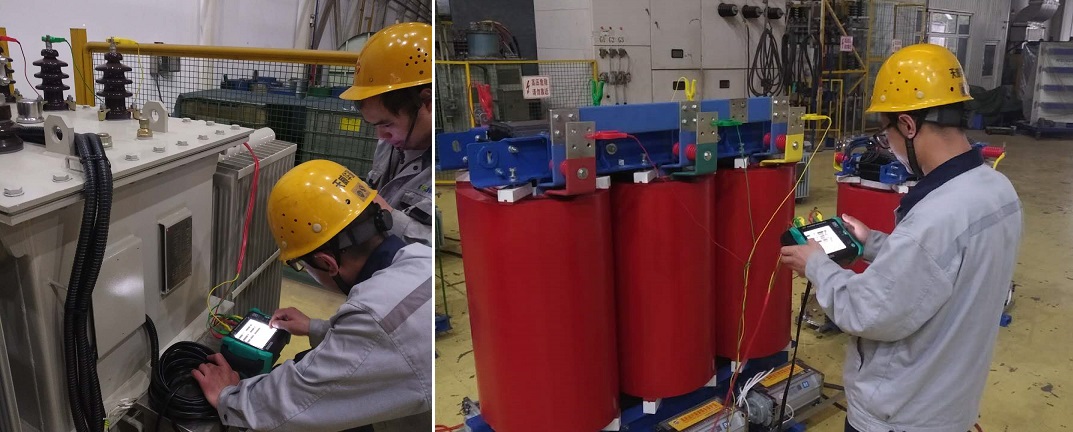

2. During testing

For small transformers: use low-voltage quick mode, measure all tap positions, and record excitation current (5–15 % of rated).

For large transformers: use high-voltage mode with 10–30 s stabilization delay; maintain a safe distance; stop immediately if insulation alarms occur.

3. Safety protection

For small units: never use high-voltage testers; test voltage ≤ 50 % of rated winding voltage.

For large units: ensure proper core grounding (resistance ≤ 10 Ω) to prevent insulation breakdown.

4. Data evaluation

Single transformer: Compare with design data—acceptable ratio deviation ≤ ±0.5 % for ≤ 35 kV, ≤ ±0.2 % for ≥ 110 kV; deviation > 0.3 % from historical values requires inspection.

Similar units: Compare excitation currents; if deviation exceeds +20 % or –30 %, inspect the transformer.

Tap changer: Check ratio continuity across taps; if irregular, service and retest after repair.

Summary:

A turns ratio tester can accurately measure transformers across a wide capacity range if proper voltage levels, insulation, and testing methods are selected. Attention to test stability, safety isolation, and data consistency ensures reliable results for both distribution and power transformers.

The 5 Most Popular transformer turn ratio testers in the World

What is the Difference between "Ratio" and "Turn Ratio" in a Transformer Testing?

How to Choose the Right Turns Ratio of CT/PT?

Why is it so Important to Test Transformer Turn Ratio?

What are the Reasons for Abnormal Voltage Output of Power Transformers?

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun