1.What is "Loop resistance" in substation and why is it called that?

(Loop Resistance) refers to the total resistance of all conductive parts within a complete current loop.

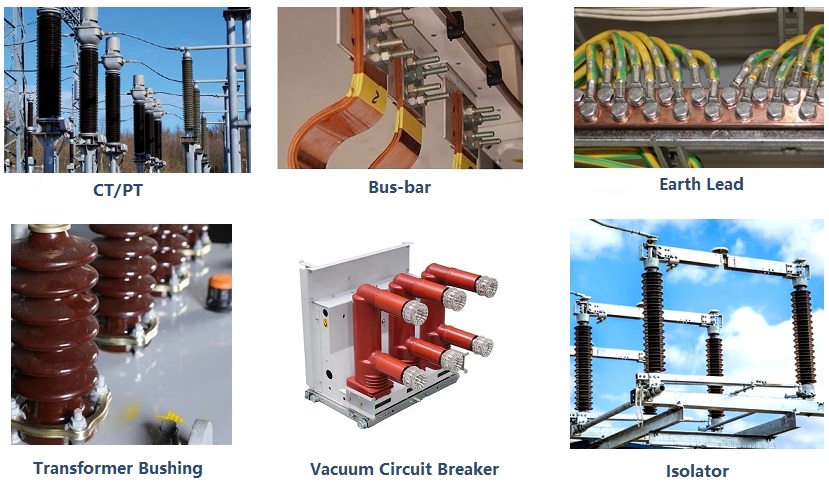

In substations or high-voltage systems, this “loop” usually refers to the current path that starts from the circuit breaker main contact, passes through conductive clamps, busbars, connection lines, current transformers, isolating switches, and finally returns to the other end, forming a closed loop.

The term “loop” is used because the current starts from the power source, flows through the load or conductive path, and then returns to the source — forming a closed circuit.

Loop resistance measurement focuses on the total resistance that hinders current flow within this loop. It encompasses the resistance of internal conductive components, connection points, and conductors themselves — a key electrical parameter in high-voltage circuits.

Loop resistance (Loop Resistance) and contact resistance (Contact Resistance) are often used interchangeably in practice, but they are not identical.

They differ in definition, composition, measurement range, and application scope (see table below):

Project

Loop Resistance

Contact Resistance

Definition

The total resistance of all conductors and connection points in a complete conductive loop.

The local resistance between two conductor contact surfaces caused by microscopic imperfections and oxide layers.

Measurement Scope

Covers all conductive parts such as contacts, cables, busbars, and connecting bolts

Limited to contact points or connector contact surfaces

Test Purpose

To evaluate the conductivity of the entire loop

To evaluate the quality of contact

In short:

Contact resistance is part of loop resistance.

Loop Resistance = Conductor Resistance + Contact Resistance

Contact resistance is "Local", while loop resistance is "overall".

High contact resistance indicates poor contact between conductors.

High loop resistance indicates a problem anywhere along the conductive path (contact points, connectors, or conductors).

|

Items |

Loop Resistance Test |

Contact Resistance Test |

|

Test Current |

Generally100A~600A DC current (according to IEC standards) |

Relatively small, generally tens of amperes or even milliamperes (depending on the object |

|

Tester |

Loop resistance tester |

Micro-ohmmeter or dedicated contact resistance meter |

|

Wiring Method |

Connecting both ends across the entire loop |

Directly connected to both sides of the contacts.

|

Identify Connection Defects:

Excessive contact resistance (due to oxidation, loosened bolts, etc.) can cause local overheating, melting of contacts, or even arcing faults.

Ensure System Stability:

Over-limit loop resistance causes excessive voltage drop, reduces power transmission efficiency, and may trigger protection misoperation or equipment derating.

Verify Equipment Condition:

Pre-commissioning or post-maintenance testing confirms installation and repair quality; periodic testing tracks equipment aging and wear trends.

Strict Power Isolation:

Disconnect all power sources, perform grounding and voltage verification before testing to prevent electric shock or equipment damage.

Clean Contact Surfaces Thoroughly:

Use sandpaper or cleaning agents to remove oxidation and grease, ensuring firm contact between test probes and the test points.

Use Dedicated High-Voltage Instruments:

Employ a high-current loop resistance tester (typically 100 A / 200 A DC output) for accurate measurement; ordinary instruments lack sufficient precision.

Isolate Non-Tested Branches:

Disconnect unrelated branches or parallel components to prevent current division that would cause abnormally low readings.

Maintain Safe Distance:

Keep an appropriate safety distance from energized high-voltage equipment to avoid induced voltage hazards.

Kingrun Transformer Instrument Co.,Ltd.