Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

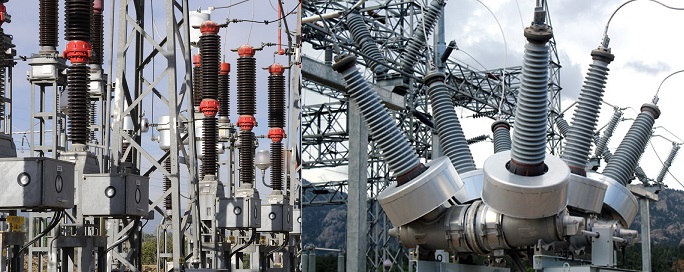

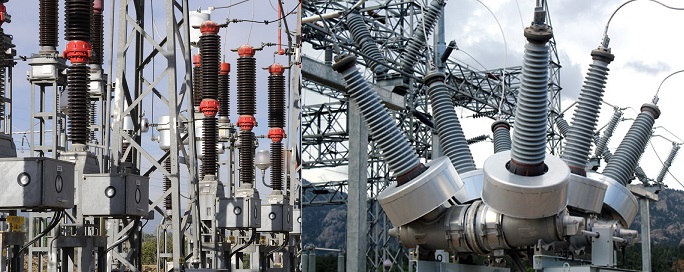

A circuit breaker refers to a switching device that can close, carry and break current under normal circuit conditions and can close, carry and break current under abnormal circuit conditions within a specified time. Generally, those above 3kV are called high-voltage switches (or circuit breakers).

Contact resistance refers to the resistance formed on the contact surface of the joint when two conductors are connected. Common causes of contact resistance are:

1. There is a layer of oxide film or dirt on the surface of the conductor (its resistivity is large);

2. The contact area between conductors is small, and sometimes the contact surface is a small point;

3. The pressure between the conductor contact surfaces is small, and a weak gap can be seen between the conductor contact surfaces with a microscope.

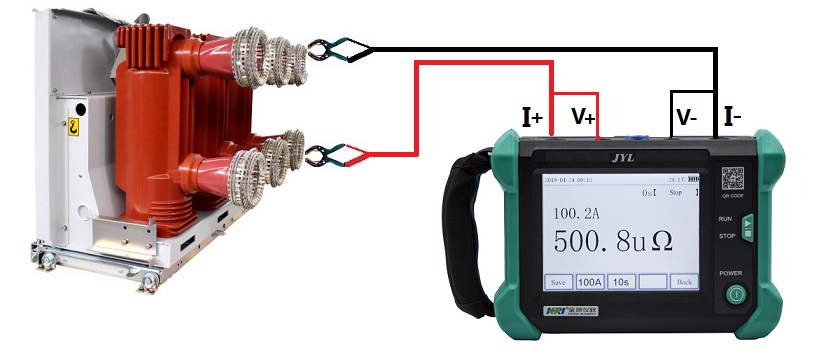

The smaller the contact resistance of the circuit breaker, the better. Generally, it is required to be below 10~20mΩ, and some circuit breakers are required to be below 100~500μΩ.

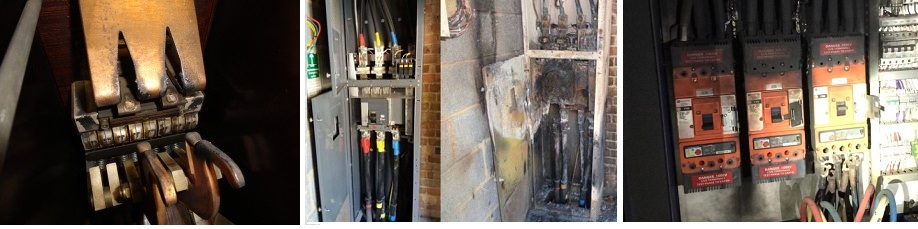

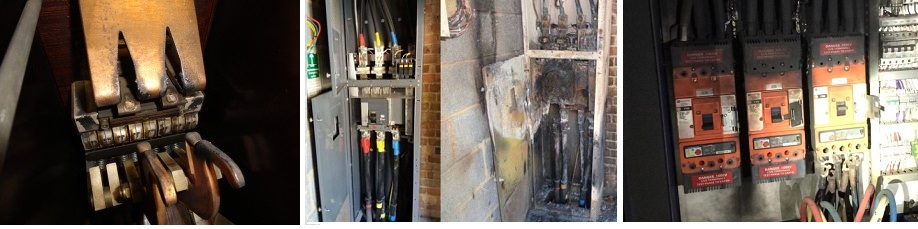

Due to the absorption current between the switch contact conductors of the circuit breaker (because the contact area between the two is reduced), the metal surface film (including dust film, oxide film, inorganic film, organic film, etc.) and electrochemical corrosion and other phenomena make the local resistance of the contact part is too big. Of course, poor contact is also one of the important reasons. If the line current is very large, when the contact resistance is too large, it will generate a lot of heat, enough to make the metal discolor or even melt

Factors affecting contact resistance

The contact resistance of circuit breakers is mainly affected by factors such as contact material, positive pressure, surface state, operating voltage and current.

1) Contact material

For mating contacts of the same specification made of different materials, there will be different contact resistances. For example, the contact resistance of mating contacts with a diameter of 1mm is ≤5mΩ for copper alloys and ≤15mΩ for iron alloys.

2) Positive pressure

The contact positive pressure of the circuit breaker refers to the force generated by the surfaces in contact with each other and perpendicular to the contact surfaces. With the increase of positive pressure, the number and area of contact micro-points also gradually increased, and the contact micro-points transitioned from elastic deformation to plastic deformation. Since the concentrated resistance gradually decreases, the contact resistance decreases. The contact positive pressure mainly depends on the contact geometry and material properties.

3) Surface condition

a. The contact surface of the circuit breaker is a looser film formed by mechanical adhesion and deposition on the contact surface due to dust, oil, etc. This film is easily embedded in the microscopic pits on the contact surface due to the particulate matter, which makes the contact The area is reduced, the contact resistance is increased, and it is extremely unstable.

b. The fouling film formed by physical adsorption and chemical adsorption is mainly chemical adsorption on the metal surface, which is produced with electron migration after physical adsorption.

4) Use voltage

When the operating voltage reaches a certain threshold, the film of the contact piece will be broken down, and the contact resistance of the contact of the circuit breaker will drop rapidly. However, because the thermal effect accelerates the chemical reaction in the vicinity of the film, it has a certain repairing effect on the film. Therefore, the resistance value is nonlinear. Around the threshold voltage, small fluctuations in the voltage drop cause the current to vary by a factor of perhaps twenty or tens of times. Making the contact resistance change a lot, and not understanding this non-linear change, can create errors when testing and using the circuit breaker.

5) Current

When the current exceeds a certain value, the Joule heat generated by the energization at the tiny point of the contact interface will soften or melt the metal, which will affect the concentrated resistance and reduce the contact resistance.

Solutions for overheating faults of circuit breaker switches

There are three ways to deal with the excessive heat of the circuit breaker switch:

①When the switch contacts of the circuit breaker are overheated, clean up the contamination on the moving and static contacts according to the technical specifications. At the same time, wipe the metal parts of the contacts to a bright state, and apply conductive paste according to the specifications.

②The contact surface is oxidized. When overhauling, treat the metal contact part to keep the contact surface flat and have metal brightness; apply an appropriate amount of power grease, and then measure the contact resistance of the isolating switch.

③ When the dynamic and static contacts of the circuit breaker are in poor contact, the bolts should be pressed during installation and maintenance, and electrical grease should be applied to the contact part to improve its electrical conductivity and prevent corrosion or oxidation of the contact part.

Other Related Articles:

Why Does the Contact Resistance Testing Need 100A or Higher?

Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

How to measure the contact resistance without changing the circuit?

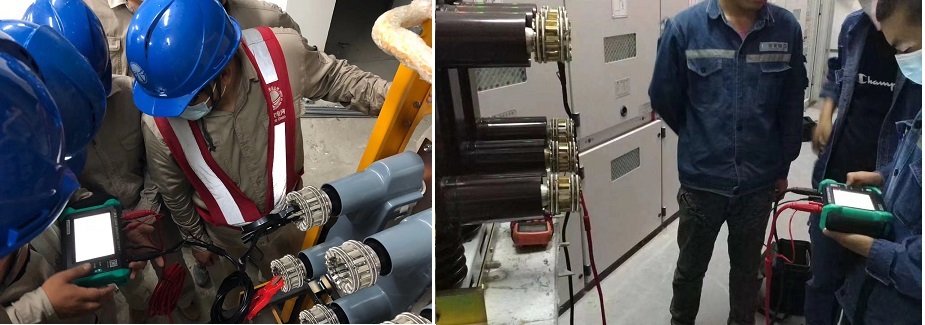

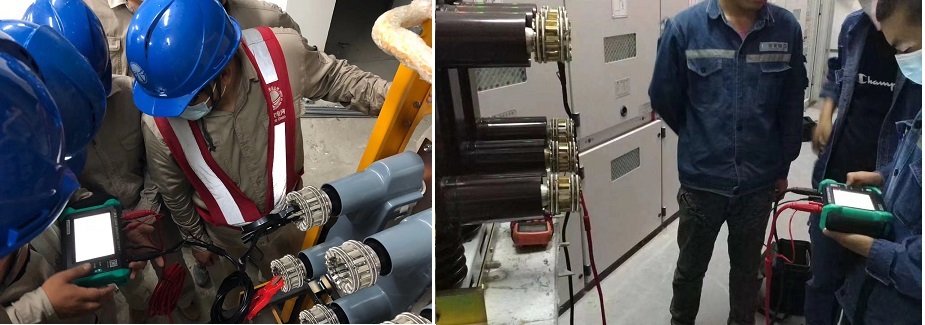

How to Correctly Test the Contact Resistance of HV Switchgear or Circuit Breaker?

Why Does Excessive Contact Resistance Occur In Electrical Secondary Circuits?

What is the Testing Checklist for 110kV/220kV Substation Acceptance and Maintenance Testing?

Handheld Contact Resistance Tester--JYL (Kingrun)

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun