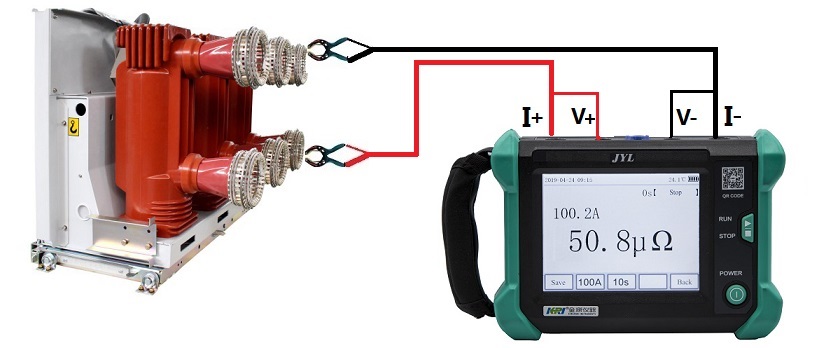

The loop resistance test work is mainly used to test the contact resistance of the dynamic and static contacts of the disconnect switch. The conductive loop resistance of the disconnect switch mainly depends on the contact resistance of the dynamic and static contacts. The existence of the contact resistance increases the conductor when it is energized. The loss of the contact point increases the temperature at the contact point, and its value directly affects the current-carrying capacity during normal operation, and to a certain extent affects the short-circuit current cut-off capacity, and is also an important data reflecting the quality of installation and maintenance work.

1. Comparison of test methods

At present, there are three main test methods for loop resistance testers:

a. Bridge method: When using a double-arm bridge to measure the resistance of the conductive loop of the disconnect switch, since the measurement loop passes through a weak current, it is difficult to eliminate the oxide film with a large resistance, and the measured resistance value is too large. When the current is small, it is difficult to form shrinkage at the contact point of the contact, that is, the shrinkage resistance cannot be measured.

b. Voltage drop method: When a DC current is applied to the circuit under test, a voltage drop will be generated on the contact resistance of the circuit, the current value and voltage value passing through the circuit are measured, and the contact resistance is calculated. The test process is cumbersome, and there are certain errors in the manual calculation of the measurement results.

c. Micro-ohmmeter method (loop resistance tester): The principle is the voltage drop principle, but the measurement, calculation and other aspects are all processed by a single chip, which greatly reduces the workload.

Most of the maintenance personnel use the method of measuring the loop resistance to judge the quality of the contact of the conductive part, and think that as long as the loop resistance is within the qualified range, the maintenance work of the conductive part is successfully completed. In fact, the circuit resistance value given in the product manual is the value of the entire conductive circuit, which includes the overall resistance and contact resistance of the terminals, conductive tubes, conductive joints, contacts and other parts, and the range is large, generally 20% The error range cannot directly reflect the change of the contact resistance of the contacts. The actual test proves that the loop resistance of 2 pairs of contacts and 4 pairs of contacts is only a few microohms, which are all within the qualified range given in the product manual. Therefore, experienced loop resistance testers can often find important data clues in the small differences in test results, and further analyze the health status of the equipment.

The test of loop resistance is a different concept from the test of DC resistance. Both tests are used to test resistance, and the DC voltage drop method is also used. Many people think that they are the same and can be used interchangeably. In fact, the two are still different. The main is resistive load, and they are all micro-resistance tests. The DC resistance tester mainly tests inductive loads, and the resistance range is relatively large. The two cannot be used interchangeably. It may damage the equipment. At present, there is no composite type of two instruments on the market, because if two kinds of equipment are combined into one device, it needs to meet both high current and inductive load with relatively large test resistance, and the cost is very high. , the device is also very large.

2. Requirements for test equipment

Contact resistance includes the additional resistance that occurs when static and dynamic contacts are in contact with each other. It consists of two parts: shrinkage resistance and surface resistance of the dynamic and static contact parts.

There are various reasons for the unqualified contact resistance of the circuit breaker, including burnout of the contact when breaking a large short-circuit current; due to the poor adjustment of the switch structure and the inability to fix it, resulting in changes in the stroke, when the overtravel is seriously unqualified, it will cause Changes in contact pressure or contact area; after the circuit breaker is debugged and installed, it has not been put into operation for a long time, causing the surface of the dynamic and static contacts to oxidize, and the contact surface resistance increases; long-term operation will deform the spring and reduce the contact pressure; long-term operation of the mechanical part The mechanical wear caused by the oil-less circuit breaker may also cause an acid reaction due to the unqualified acid value of the insulating oil, which may erode the contact surface. Or floating impurities in the oil, after the short-circuit current is broken between the dynamic and static contacts. Residual particulate carbonaceous, metal powder increases the contact resistance.

pressure or contact area; after the circuit breaker is debugged and installed, it has not been put into operation for a long time, causing the surface of the dynamic and static contacts to oxidize, and the contact surface resistance increases; long-term operation will deform the spring and reduce the contact pressure; long-term operation of the mechanical part The mechanical wear caused by the oil-less circuit breaker may also cause an acid reaction due to the unqualified acid value of the insulating oil, which may erode the contact surface. Or floating impurities in the oil, after the short-circuit current is broken between the dynamic and static contacts. Residual particulate carbonaceous, metal powder increases the contact resistance.

Therefore, the comprehensive requirements for test equipment should consider the following aspects:

The above analysis illustrates the importance of ensuring reliable measurement of the circuit resistance of the isolation switch, and the necessity of detecting the circuit resistance. No matter when the product leaves the factory, before the product is put into operation or during regular maintenance, it is necessary to measure the loop resistance.

3. Summary

Due to the different structures and rated currents of the disconnect switch contacts, the circuit resistance of the contacts is not uniformly specified. In order to make the maintenance work of the isolating switch scientific and standardized, it is recommended that the isolating switch manufacturer indicate the rated value and allowable deviation of the contact loop resistance in the product installation and operation manual. For products that have been delivered, if there is no such parameter in the manual, you can ask for it from the manufacturer separately, or you can use the detector to test the new product before it is put into operation, and record the pressure value in the book for future use. At the same time, it is hoped that the manufacturer can indicate the contact resistance value of the contact parts of various rated current levels as much as possible, so as to facilitate the comparison before and after maintenance. In addition, it is recommended to add battery power to the detector to facilitate measurement in places without AC power.

Other Related Articles:

Why Does the Contact Resistance Testing Need 100A or Higher?

Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

How to measure the contact resistance without changing the circuit?

How to Correctly Test the Contact Resistance of HV Switchgear or Circuit Breaker?

Why Does Excessive Contact Resistance Occur In Electrical Secondary Circuits?

What is the Testing Checklist for 110kV/220kV Substation Acceptance and Maintenance Testing?

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun