Dielectric loss refers to the sum of polarization loss and conductivity loss caused by transformer oil under the action of alternating electric field. The dielectric loss factor can reflect the insulation characteristics of the transformer, reflect the aging degree of the transformer oil under the action of electric field, oxidation and high temperature, and reflect the degree of pollution such as polar impurities and charged colloids in the oil. In the long-term use of the transformer, the dielectric loss factor test can reflect the operation status of the transformer oil.

1. The influence of impurities.

During the installation process, there are impurities such as dust in the oil or solid insulation material of the transformer, and after running for a period of time, the colloidal impurities gradually precipitate. Colloidal particles are small in diameter and diffuse slowly, but have a certain amount of active energy. Particles can be automatically coalesced, from small to large, into a coarse dispersion system, in a non-equilibrium unstable state, when beyond the range of colloidal, due to gravity and accumulation. After the presence of sol in the oil, when the sediment exceeds 0.02%, it may cause the conductivity to exceed the normal conductance of the medium by several times or dozens of times, resulting in an increase in the dielectric loss value.

2. The influence of transformer structure.

From the analysis of transformer manufacturing structure, some transformer manufacturers have considered the cancellation of the oil purifier (thermosiphon) from the perspective of reducing oil leakage from the transformer, which has a certain impact on the increase of the transformer oil dielectric loss factor. If the transformer is equipped with an oil purifier that is conducive to the stability of the insulating oil quality, it can "suck out" the moisture inside the insulation during the operation of the transformer, improve the electrical properties of the insulation, and thus slow down the increase in moisture in the insulation.

3. The impact of microbial contamination.

Microbacterial infections are mainly caused by bacterial biopsy during installation and overhaul. Due to pollution, oil contains water, air, carbonides, organic matter, various minerals and trace elements, thus constituting the basic conditions for the growth, metabolism and reproduction of fungal organisms. Because microorganisms are rich in protein and have colloidal properties, the contamination of oil by microorganisms is actually a pollution of microbial colloids, and microbial colloids are charged, so that the conductivity of the oil is increased, so the conductivity loss also increases. Transformer oil is located in a fully sealed, hypoxic and lightless body, and the microorganisms present in the oil are anaerobic. The mediator damage test is performed after a long period of placement, especially in colorless transparent glass bottles, and the medial loss value will be reduced. Transformers in different periods of load is different, the operating oil temperature is different, the microorganisms at different temperatures the propagation rate is also different, the oil temperature in the range of 50 ℃ ~ 70 ℃ running, the fastest propagation speed, so the relative increase in the loss of the relatively fast. Therefore, the temperature has a great influence on the growth of microorganisms in the oil and the performance of the oil, and the media loss factor in winter is relatively stable.

4. The influence of metal ions.

The wear or corrosion of the copper metal components of the transformer body (such as the wear of the oil pump shaft or impeller, the corrosion of the exposed copper leads), the serious overheating or burning loss of the winding copper wires, etc. will cause the copper ions to dissolve into the oil ff1, which will increase the concentration of copper ions in the transformer oil, resulting in an increase in the secondary loss.

5. The influence of water content.

Although the insulation material is dried in the manufacturing process of transformers and other electrical equipment, there is still moisture in the deep layer, and if the protective measures are improper during transportation and installation, the insulation material will be damp again, and the breathing system will enter the moisture and penetrate into the oil through the oil surface. In addition, solid insulation materials and transformers in the operation process, due to the oxidation of transformer oil oxidation thermal cracking and the formation of moisture, insulation oil at the operating temperature and the presence of dissolved oxygen, its oxygenation will be accelerated, resulting in organic acids and water, which will lead to excessive moisture in the oil. For pure oil, when the water content in the oil is low (such as 30mg/L-40mg/L), the dielectric loss of the oil has little effect, but when the water content in the oil is greater than 60mg/L, the dielectric loss factor increases sharply.

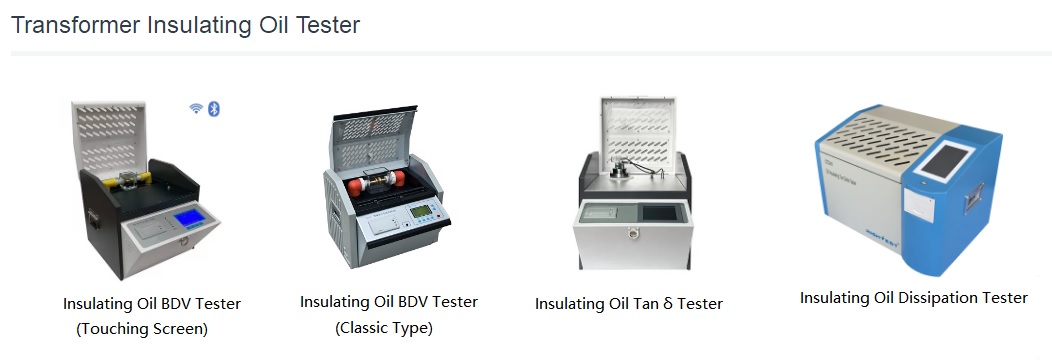

GTD-61A automatic oil Tan Delta Tester and volume resistance tester oil dielectric loss tester, Highly automatic, temperature rise, dielectric loss measurement and resistance measurement can be completed at one time.

Kingrun Transformer Instrument Co.,Ltd.