The transformer turns ratio (TTR) test is one of the key diagnostic procedures for evaluating the electrical and magnetic conditions of a power transformer’s windings and core. It is conducted throughout the entire transformer lifecycle, including factory acceptance tests (FAT), type tests, site acceptance tests (SAT), and routine operation and maintenance.

New and old transformers differ significantly in testing purpose, procedures, and data interpretation, mainly due to differences in equipment condition, testing environment, and technical standards. This article analyzes these differences based on international standards (IEC 60076, IEEE C57.12) and real-world cases, providing reference value for power system maintenance and reliability assessment.

For new transformers, the primary goal is conformity verification—ensuring that the winding turns ratio, tap changer positions, and vector group strictly match the design specifications. According to GB 50150-2016 and IEC 60076-1, the deviation of the measured ratio at the rated tap should not exceed ±0.5%, guaranteeing the product’s compliance before commissioning.

In contrast, old transformers emphasize condition diagnosis. The goal is to identify hidden faults accumulated during operation—such as inter-turn short circuits, tap changer oxidation, or magnetic circuit deterioration—by comparing the latest measurements with historical records. Although the acceptable deviation range remains the same, trend analysis becomes crucial. A gradual drift in ratio values often signals winding deformation or contact wear.

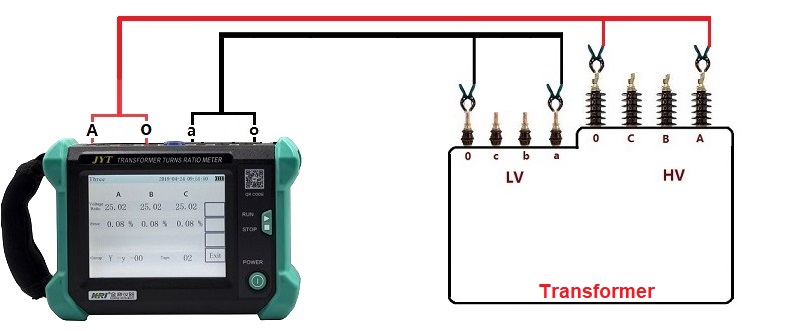

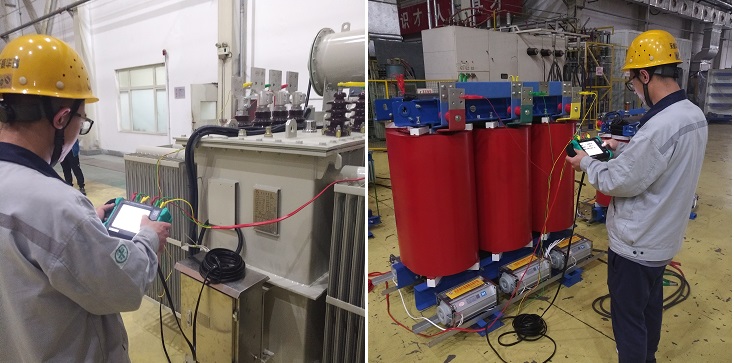

Testing of new transformers prioritizes efficiency and precision. Fully automatic TTR testers are typically used, employing the bridge balance or low-voltage excitation method to simultaneously measure ratio, phase, and polarity. Modern instruments achieve accuracies up to ±0.2%, support three-phase concurrent measurement, and automatically generate standardized reports.

For instance, during FAT of a 35 kV distribution transformer, a digital automatic tester completed full tap position measurements in under 20 minutes with results directly stored in the inspection database.

Testing of old transformers, however, must consider aging effects and potential contact issues. A combined approach—traditional dual-voltmeter method with modern instrument verification—is often adopted. Since aged equipment may have oxidized terminals or mechanical tap changer wear, applying a slightly higher test voltage (e.g., 250 V instead of 100 V) helps reduce magnetic imbalance and improve accuracy.

In a 110 kV transformer that had been in operation for 15 years, the dual-voltmeter method detected a 1.8% deviation in the C-phase ratio. A subsequent automatic TTR test located the fault at a worn tap changer contact, confirming the effectiveness of the combined diagnostic approach.

For new transformers, deviations are typically manufacturing-related—caused by coil winding errors, poor tap changer assembly, or inaccurate mechanical positioning.

In one case, a new 10 kV transformer exhibited a 1.2% ratio deviation at FAT. Investigation revealed incomplete contact between tap changer terminals; after re-polishing and tightening, the deviation dropped to 0.3%, meeting GB and IEC acceptance limits. Moreover, for large-capacity units, testing at 250 V excitation provides more stable readings than at 100 V, due to improved core magnetization.

In old transformers, deviations mainly arise from operational wear and thermal or electrical stresses. Key factors include:

Winding insulation aging or inter-turn short circuits, causing actual turns ratio changes.

Oxidized tap changer contacts, leading to unstable contact resistance and incorrect ratio readings.

Increased core losses or magnetic degradation, affecting magnetic coupling and inducing measurement instability.

For example, a 35 kV transformer that had operated for 20 years showed its ratio deviation increasing from 0.2% to 1.5%. Disassembly confirmed minor winding deformation caused by past short-circuit forces, illustrating the necessity of periodic ratio trending.

New transformers strictly follow GB/T 1094.1-2013, IEC 60076, and ANSI C57.12 standards. Measured values are compared directly with nameplate data, and any deviation beyond specified limits renders the unit non-compliant for energization. The test results serve mainly as acceptance documentation and baseline technical records.

For old transformers, testing is performed according to DL/T 596-2021 preventive test code or IEEE Std C57.152-2013, using a dual-criterion approach: compliance with standard limits and comparison with historical data. Although the same tolerance (±0.5%) applies, the rate of change between successive tests is the main diagnostic indicator.

Typically, a variation of ≤2% compared to previous results under the same temperature is considered acceptable. In a distribution network renovation project, ten aged 10 kV transformers were retested over a five-year period. Two units exhibited an annual ratio drift exceeding 0.8%, prompting preemptive replacement and avoiding future in-service failures.

The TTR test, while uniform in principle, serves different technical purposes for new and old transformers. New transformer tests ensure manufacturing quality and design conformity, whereas old transformer tests focus on detecting deterioration and preventing unplanned outages. Understanding these differences in objectives, instrumentation, error sources, and data analysis allows maintenance teams to optimize transformer life-cycle management in accordance with modern international standards.

Other Related Articles:

Why Does the Contact Resistance Testing Need 100A or Higher?

Hazards and Treatment of Excessive Contact Resistance of Circuit Breakers or HV Switches

How to measure the contact resistance without changing the circuit?

How to Correctly Test the Contact Resistance of HV Switchgear or Circuit Breaker?

Why Does Excessive Contact Resistance Occur In Electrical Secondary Circuits?

What is the Testing Checklist for 110kV/220kV Substation Acceptance and Maintenance Testing?

More Transformer Testers from Kingrun

Kingrun Transformer Instrument Co.,Ltd.