Before transformer leaving the factory, manufacturers conduct a comprehensive series of tests called "Factory Acceptance Testing" (FAT) to assess their quality, functionality, and service life. These tests include transformer turns ratio and vector group testing, winding resistance measurement, no-load testing, load testing, capacity testing, power frequency withstand voltage testing, inductive Hipot testing, insulation resistance testing, dielectric loss testing (tan delta testing), partial discharge testing, and impulse voltage testing.

These tests are crucial for ensuring that the transformers meet all necessary standards and specifications to achieve reliable performance. They also ensure the quality, safety, and durability of the transformers in their operational environments. Below, we will provide detailed descriptions of each test item, including their principles and significance.

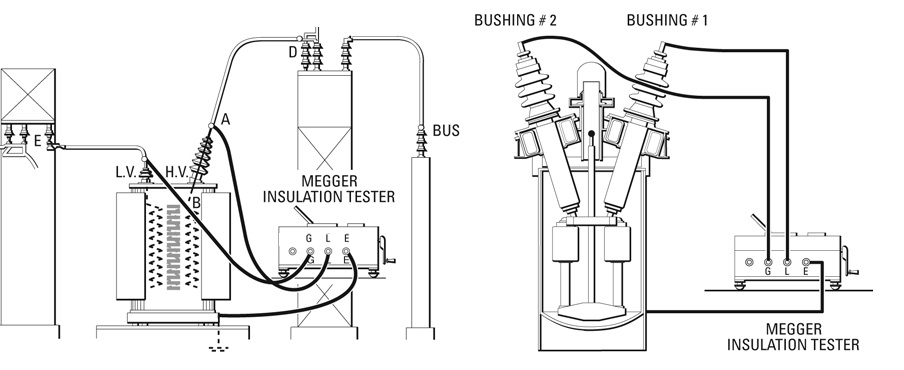

1. Transformer winding insulation resistance testing

The insulation resistance test for new transformers is a method used to assess the integrity and quality of the transformer windings' insulation. In this test, typically, the insulation resistance between the high-voltage winding and the low-voltage winding with respect to the tank is measured, as well as the insulation resistance between the low-voltage winding and the high-voltage winding and the tank.

The principle of this test relies on Ohm's law, which describes the relationship between voltage, resistance, and current. By applying a certain DC voltage and measuring the corresponding current, the insulation resistance between windings and ground can be calculated. The purpose of the insulation resistance test is to detect any leakage current between windings or between windings and ground, and to evaluate the integrity and quality of the insulation.

The insulation resistance test can detect the insulation integrity of new transformers, identify any potential leakage issues, and assess insulation quality. Higher resistance values typically indicate good insulation integrity, while lower resistance values may suggest potential insulation problems.

Recommended tester:JYM

2. On-load tap-changer testing

The on-load tap changer test for new transformers is a method used to evaluate the switching performance of the tap changer while the transformer is under load conditions. The on-load tap changer is the only moving part in the transformer circuit, hence its assessment is crucial. The test involves examining the sequence of operations, measuring the switching time, and evaluating parameters such as transition waveforms, transition time, instantaneous transition resistance, and three-phase synchronization of the on-load tap changer.

During this test, the transformer is connected to a load, and the on-load tap changer is continuously switched to different tap positions to simulate real-world operating conditions. The principle of the test lies in observing and recording the transformer's voltage, current, and other performance parameters during tap changer operation to assess its stability and reliability.

This test enables the evaluation of the on-load tap changer's reliability, the transformer's load regulation performance, and assessment of temperature rise when switching tap positions.

Recommended tester: JYK- I

3. DC winding resistance testing

The principle of this test involves measuring the resistance values of various windings of the transformer to inspect the quality of winding connections and electrical characteristics. Typically, this test includes resistance measurements of each winding of the transformer, such as the high-voltage winding, medium-voltage winding, and low-voltage winding.

During the test, test instruments are connected to different windings of the transformer, and a known current is applied. According to Ohm's law, the resistance values of each winding can be calculated based on the measured voltage and current values. By comparing the measured resistance values with the design values, the quality of winding connections, poor contacts, open circuits, and short circuits can be evaluated and identified. Additionally, it verifies whether the transformer winding design meets specification requirements, ensuring the stability and reliability of the transformer.

Recommended tester:

JYR9310 (Handheld / Cu&Au/Temp. Convert/Single phase)

JYR-10C (Economy / Single phase)

JYR-50S (High current / Comprehensive Testing / Three phase)

4. Short circuit imedance testing

The transformer short-circuit impedance test is primarily used to measure the short-circuit impedance value of a transformer. This value is determined by the relationship between the voltage and current on the primary side when the secondary side of the transformer is short-circuited and the primary side is supplied with the rated current. The short-circuit impedance test helps to understand the internal inductive and resistive characteristics of the transformer.

The short-circuit impedance value can validate whether the transformer's design meets specifications and if there are any defects in the manufacturing process. If the short-circuit impedance value deviates significantly from the design value, it may indicate internal issues within the transformer, such as incorrect winding turns or improper geometric configuration of the windings. Additionally, this test can evaluate the core losses of the windings, short-circuit current, voltage regulation performance, and the mechanical strength of the transformer.

Recommended tester: JYW6300

5. AC Hipot testing

The AC Hipot test of windings along with bushings is one of the most effective methods to evaluate the insulation strength of transformers. The principle of the test involves applying a high voltage, higher than the rated voltage but for a very short duration, to one end of the transformer while grounding the other end. If the insulation does not break down or exhibit surface flashover, it indicates that the insulation strength can withstand the applied high voltage, thus passing the Hipot test.

The AC Hipot test can detect major insulation defects such as moisture ingress and concentrated defects, including main insulation cracking, winding displacement, insufficient clearance of lead insulation, and contamination by water and dirt on the insulation. Additionally, it can identify local insulation defects through the relationship between current and leakage current.

Compared to AC voltage, DC voltage tests are more effective in identifying end insulation defects, as the voltage is divided by the insulation resistance under DC conditions. However, AC Hipot testing may exacerbate some existing weak points in the insulation. Therefore, prior to performing the AC Hipot test, it is essential to conduct preliminary tests on the transformer, including insulation resistance, polarization index, leakage current, and dielectric loss measurements. Only if these preliminary test results are satisfactory should the AC Hipot test be conducted. Otherwise, necessary corrective actions should be taken, and once all parameters meet the required standards, the AC Hipot test can be performed to prevent unnecessary insulation damage.

The test voltage for ACHipot testing is usually generated using a high-voltage test transformer. For transformers with large capacitance, a series resonance circuit can also be used to generate the high voltage.

Recommended tester: JYDHV

6. No-load(open-circuit)/Load testing

The no-load test(open-circuit) test of a transformer is a standardized testing method used to assess its performance and quality. During this test, the secondary winding of the transformer remains disconnected from any load, while the primary winding is energized with rated voltage without transmitting power. Various parameters of the transformer are measured during the test, including open-circuit current, no-load losses, voltage regulation performance under load variation, losses in windings and core, as well as insulation characteristics.

The on-load test of a new transformer is a method used to assess its performance and stability under load conditions. The principle of the on-load test involves applying a load to the secondary winding of the transformer and observing and measuring various performance parameters while under load. By monitoring and recording parameters such as output voltage, input current, power factor, and temperature, the on-load test evaluates the transformer's voltage regulation performance under load variations, measures its power losses, and assesses its temperature rise to ensure proper thermal performance.

Recommended tester: JYW6100

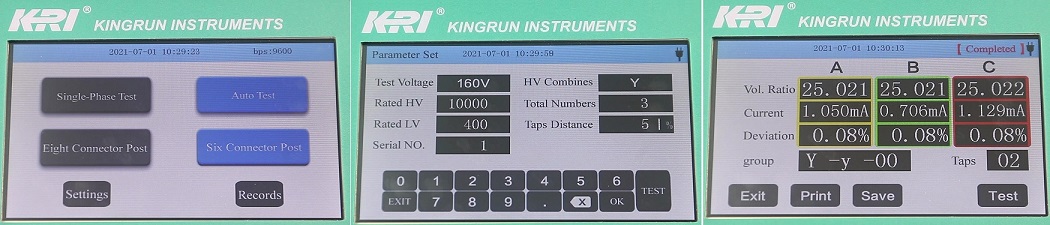

7. Transformer Turns Ratio Testing

There is a polarity and transformation ratio relationship between the windings of the transformer. When several windings need to be connected to each other, the polarity must be known to make the connection correctly. If the transformer ratio and wiring group are inconsistent, there will be unacceptable circulating currents. Therefore, when the transformer is tested at the factory, the purpose of checking the transformation ratio, polarity and wiring group of the transformer is to check the correctness of the winding, the number of turns, the connection of the lead and the tap lead, the position of the tap changer and the marking of each outgoing terminal. For the installed transformer, it is mainly to check whether the position of the tap changer and the marking of each outgoing terminal are correct compared with the nameplate of the transformer; when the transformer fails, check whether there is an inter-turn short circuit in the transformer, etc.

The voltage difference of each tap position of the winding is not more than ±0.5% (rated tap position), and the voltage difference is not more than ±1.0% compared to the initial value.

Recommended tester:

JYT (Handheld)

JYT-A (Leading type)

JYT-B (Angle test / Neutral point / Scott / Z connection)

8. Temperature rise (heat-run)testing

This test is mainly to check the structural performance of the transformer, specifically to check whether the transformer can be cooled quickly, that is, whether the heat generated by the total loss during the operation of the transformer can be quickly dissipated, and whether it meets the requirements of the IEC standard. Temperature rise, as well as the limit value of winding temperature rise, also check whether some other components have local overheating phenomenon, such as iron core, fuel tank and structural parts, etc. Generally, after insulation, loss, voltage ratio and DC resistance tests, according to the nameplate data or relevant regulations.

The principle of the heat-run test is to apply a rated load current to the winding of the transformer, run it continuously for a period of time, and then measure the temperature rise of the winding. Typically, temperature rise tests are conducted under full load conditions of the transformer to simulate operating conditions in actual operating environments.

Recommended tester: JYR-40E

9. Transformer oil breakdown voltage test(Oil BDV testing)

Transformer oil breakdown voltage test(oil BDV test) is one of the chemical analysis methods for transformer oil. It is measured by AC high voltage breakdown method, which is a necessary measurement item for transformers in new installation, overhaul or preventive test requirements.

The principle of the oil breakdown voltage test is to apply a high voltage electric field to the transformer insulation oil for a certain duration and monitor for any occurrence of breakdown. Typically, the high voltage applied during the test exceeds the transformer's rated voltage to ensure the insulation oil's withstand voltage capability.

This test assesses the quality of insulation oil in new transformers for the presence of moisture, impurities, or defects, while also verifying the oil's withstand voltage capacity. It aims to ensure that no breakdown occurs in the insulation oil during the transformer's operation, thus ensuring the transformer's safety and reliable performance.

Recommended tester:JY6611

10. Transformer Oil Tan Delta Test(oil dielectric loss testing)

The oil Tan Delta test for new transformers is a method used to evaluate the dielectric loss characteristics of insulation oil. The Tan Delta, also known as the dissipation factor, quantifies the energy loss of dielectric materials in an alternating electric field, reflecting the insulation performance and quality of the insulation oil.

The principle of this test involves applying an alternating voltage to the transformer insulation oil, measuring the phase difference between voltage and current, and subsequently calculating the Tan Delta of the insulation oil. Typically, a smaller Tan Delta indicates better insulation performance of the oil.

This test assesses the quality of the insulation oil in new transformers. By measuring the Tan Delta of the insulation oil, it evaluates the quality and performance of the oil, checks for any impurities or defects, and helps prevent the occurrence of insulation breakdown phenomena.

Recommended tester: JYC

Kingrun Transformer Instrument Co.,Ltd.

More Transformer Testers from Kingrun

What are the Acceptance Testing Items for Transformer Installation, Commissioning and Repair?

What tests Must be done(FAT) before a transformer leaves the factory?

What is the difference between transformer "Type testing"and "Factory acceptance testing"(FAT)?

What is the "Type Test" of Transformer( with example analysis)?